Digital Counter for panel thickness is different from analog counter.

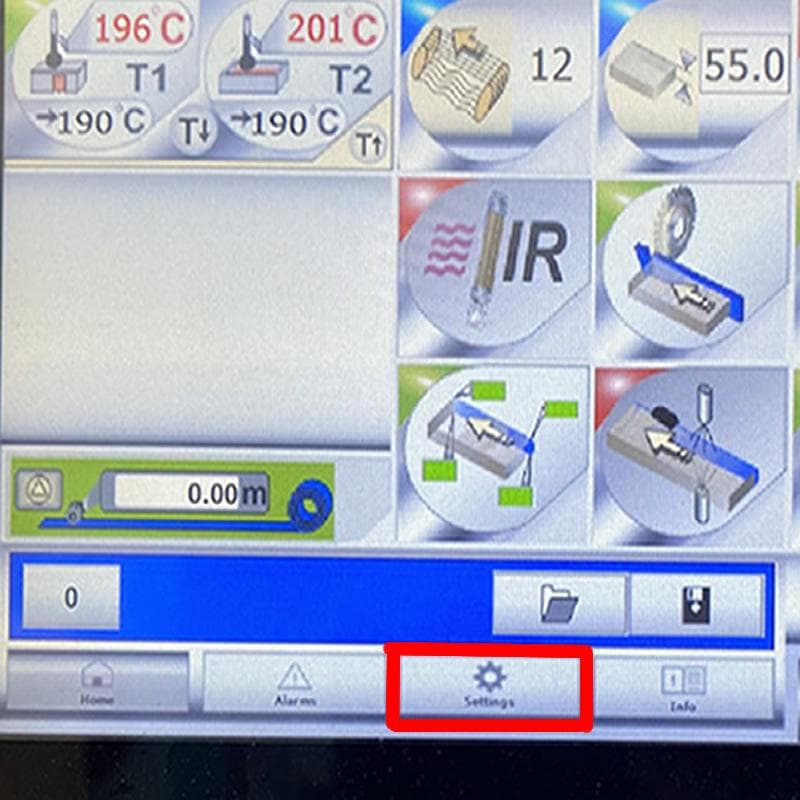

If you notice a discrepancy between the manual (analog) panel thickness counter and the digital display counter on your NikMann-2RTF edgebander, it is crucial to address the issue promptly.

Accurate panel thickness settings are essential not only for high-quality edge banding results but also for preventing premature wear or damage to internal components such as pressure rollers, trimming units, and glue application systems.

For more information, please call: 1300 436 792

Why This Matters

The thickness setting directly influences the alignment of several key units inside the machine. If the actual panel thickness differs from what the system believes it is processing, you could experience:

- ✅ Poor edge adhesion;

- ✅ Inconsistent trimming or corner rounding;

- ✅ Increased wear on tools;

- ✅ Possible machine errors or jams;

To maintain the longevity, precision, and reliability of your NikMann-2RTF edgebander, please follow the steps below to resolve any mismatch between the analog and digital counters.

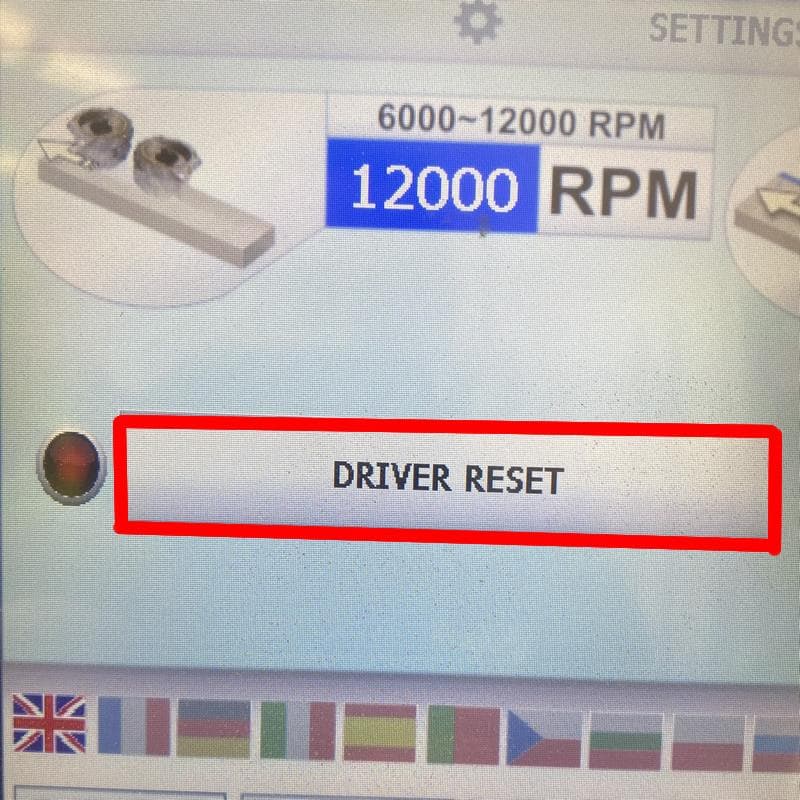

✅ Steps to Synchronize the Manual and Digital Counters:

✅ Still Seeing a Mismatch?

If the issue persists after calibration, there may be a sensor fault, encoder misalignment, or a PLC programming issue. In such cases, do not continue operation, as incorrect settings can cause significant wear or malfunction. Instead, contact Forza Machinery’s technical support team for immediate assistance. Our technicians can guide you through advanced diagnostics or dispatch service if necessary.

You may also like

WOODWORKING MACHINERY SERVICE

From emergency repairs to scheduled maintenance, sourcing spare parts or specifying a new woodworking machine - call 1300-436-792 for our expert advice and support.