🔴 ALARM-1 Motor Overheat Protection

ALARM - 1 (Motor PTC Overheat Protection) on NikMann edgebanders indicates that a motor has overheated based on its PTC (Positive Temperature Coefficient) sensor feedback.

🔍 What the Alarm Means:

PTC sensors are built into motors to monitor their temperature.

If the motor exceeds a safe temperature threshold, the PLC (Vision controller programmed in VisiLogic) detects the high resistance from the PTC and triggers Alarm 1.

This prevents damage to the motor by stopping operation until it cools down or the issue is resolved.

For more information, please call: 1300 436 792

✅ How to Troubleshoot & Reset Alarm - 1:

1.Let the Motor Cool Down

Power off the machine and allow the motor to cool for at least 15–30 minutes.

Check if the ambient temperature or duty cycle is too high.

2.Check for Mechanical Blockage or Overload

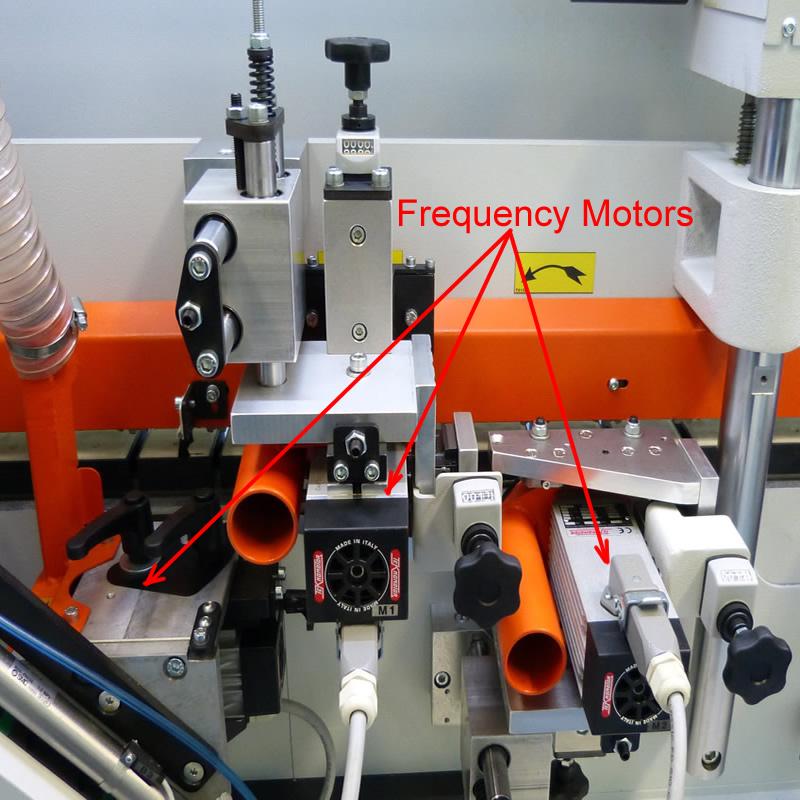

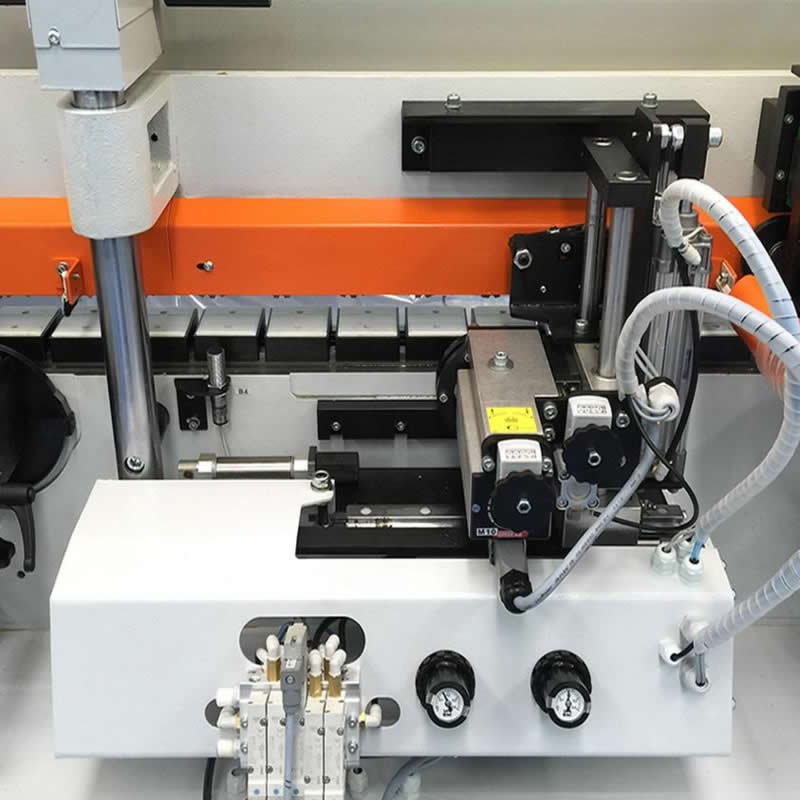

Inspect the motor connected to the alarm (e.g., glue unit, milling, trimming motor).

Look for signs of:

Jammed tooling

Binding bearings

Glue buildup

Over-tensioned belts or feed chains

3.Inspect Cooling Fans and Airflow

Ensure cooling fans are working and air inlets are not blocked by dust or debris.

4.Check the Motor’s Power Supply

Fluctuations or drops in voltage can lead to motor overheating.

Check connections for looseness or signs of arcing.

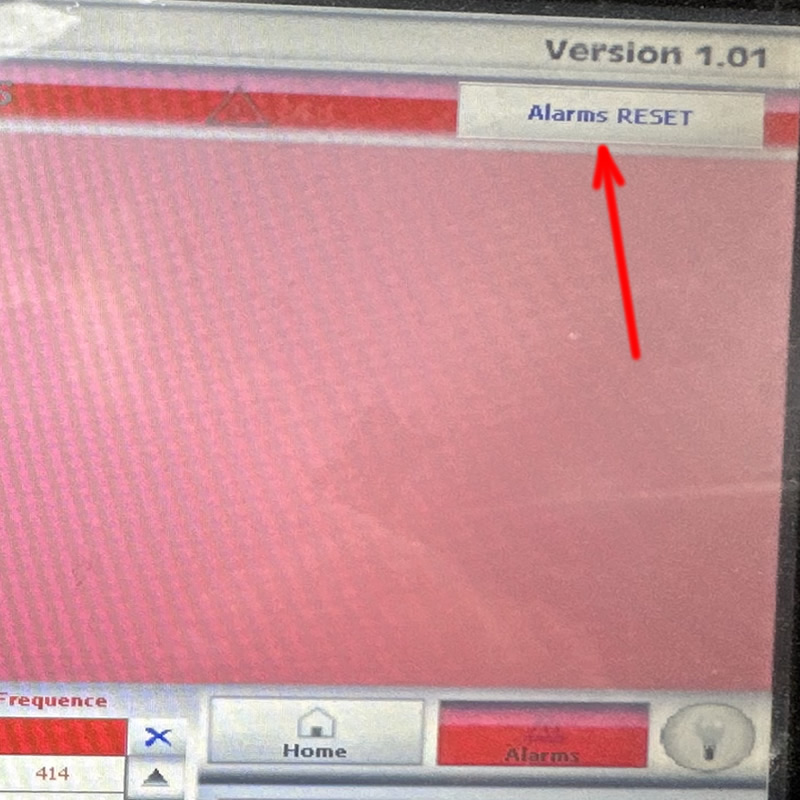

5.Read the Alarm via the HMI (Vision Controller)

Navigate to the alarm log or diagnostics page on the integrated HMI panel.

Identify which motor triggered the PTC alarm.

6.Reset the Alarm

Once the cause is corrected and the motor has cooled:

Use the HMI to acknowledge or reset the alarm.

Some models require power cycling the machine to fully clear the error.

🧰 Preventative Tips:

Perform regular cleaning and motor maintenance.

Avoid excessive load or extended continuous use beyond rated capacity.

Ensure proper ventilation inside the electrical cabinet and motor covers.

Keep the machine in a temperature-controlled environment if possible.

WOODWORKING MACHINERY SERVICE

From emergency repairs to scheduled maintenance, sourcing spare parts or specifying a new woodworking machine - call 1300-436-792 for our expert advice and support.