Edgebander NikMann wont Start

NikMann edgebanders are engineered for reliability and precision, offering professional-grade performance with minimal downtime. These high-performance machines are equipped with integrated all-in-one Programmable Logic Controllers (PLCs), which include built-in Human Machine Interface (HMI) panels. This integration allows for intuitive operation, fast diagnostics, and smooth troubleshooting processes. The sophisticated control system is based on Vision hardware and is programmed using the VisiLogic development environment.

VisiLogic is a comprehensive tool that allows for the development of Ladder Logic programs, HMI interface customization, and communication protocol setup. These advanced capabilities enable seamless machine control and straightforward system integration. In most cases, the HMI will display errors, alerts, or warnings if there is an operational issue. However, if the screen shows no errors and the NikMann edgebander still won’t start, this indicates a less obvious issue that may require a closer inspection.

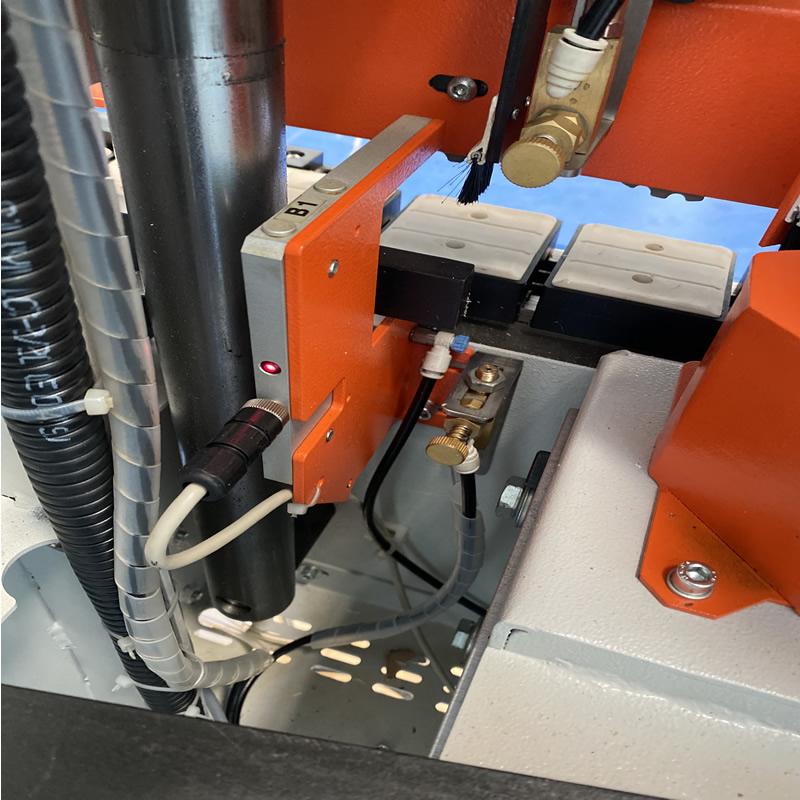

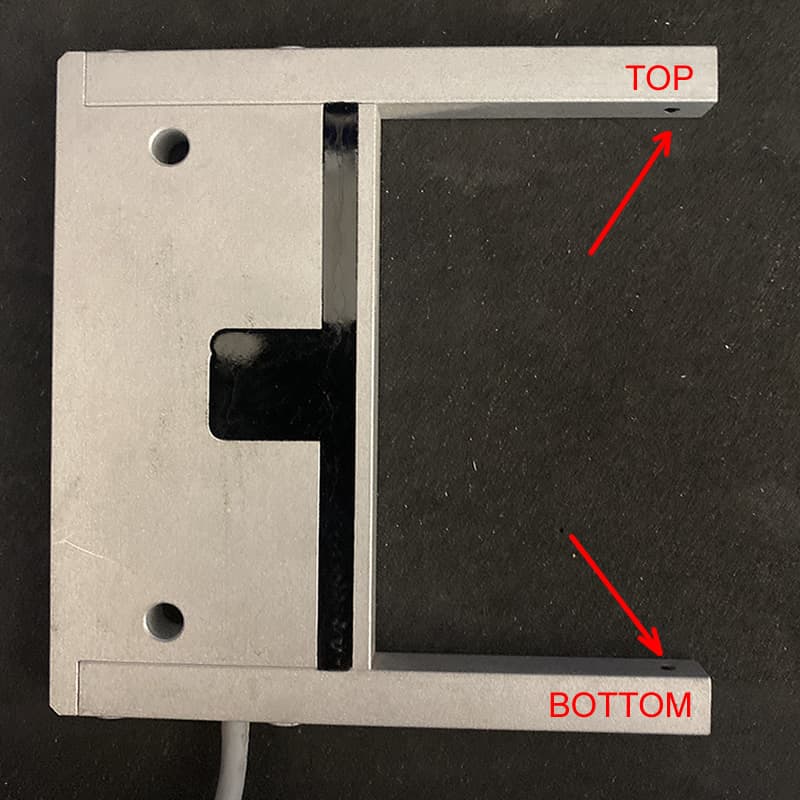

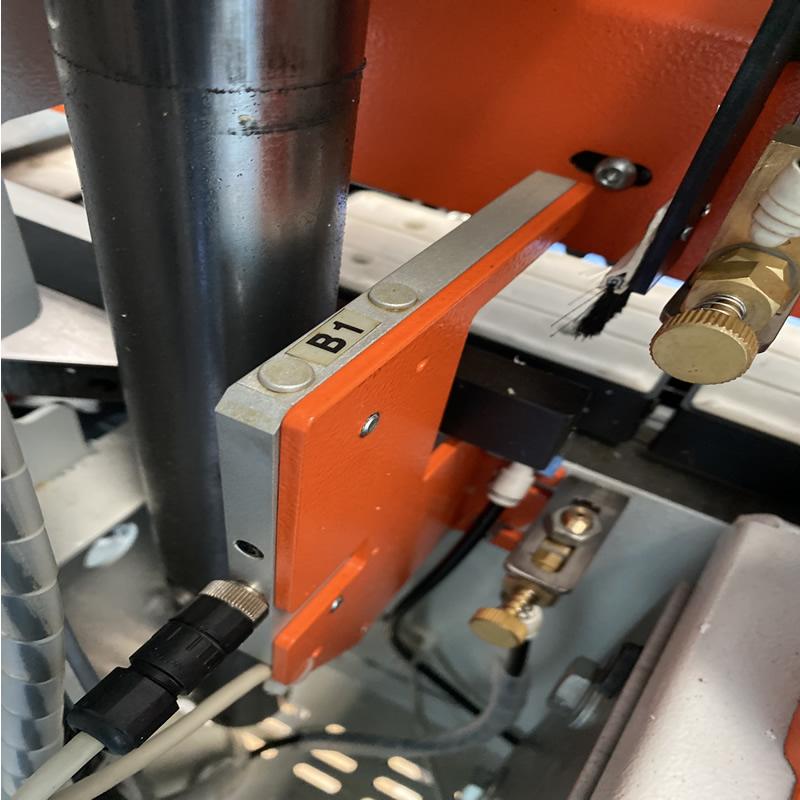

One of the first things to check is sensor B1, which plays a critical role in the machine’s startup sequence. B1 is typically located near glue pot /LHS of machine/. If the indicator light on sensor B1 is ON, this means the sensor is detecting an obstruction, misalignment, or fault condition. This detection prevents the system from initiating the startup procedure, even if no errors are visually displayed on the HMI panel.

To resolve this, inspect the area around sensor B1 for any debris, material blockage, or mechanical misalignment that could be triggering the sensor. Sometimes, a simple obstruction or a minor shift in the position of moving parts can cause the sensor to remain active. Once the obstruction is cleared or alignment is corrected, the indicator light on sensor B1 should turn OFF. Only then will the system allow a successful startup.

In cases where the indicator light on sensor B1 is off and the machine still won’t start, other factors might be at play. These include:

- ✅ Emergency stop buttons not fully released;

- ✅ Power supply fluctuations or tripped circuit breakers;

- ✅ PLC not fully booted or in a halted state;

- ✅ Internal safety interlocks that may have been triggered;

If you've checked these basic areas and the machine still fails to start, it's best to contact Forza Machinery’s technical support team. Their experienced technicians can troubleshoot issues quickly over the phone, often avoiding the need for an on-site visit. Using their deep knowledge of the NikMann system and remote guidance, they can help operators identify problems, reset systems, or guide physical inspections step-by-step.

In summary, if your NikMann edgebander shows no errors on the screen but won’t start, sensor B1 should be your first checkpoint. Ensure its indicator light is OFF and that no obstructions or faults are being detected. For persistent issues, Forza Machinery’s responsive support team is ready to assist, ensuring your machine returns to operation as quickly and efficiently as possible.