Why Edge Banding is Essential?

An edgebander is a machine used in woodworking to apply a thin strip of material, known as edge banding, to the exposed edges of various wood-based panels, such as plywood, particle board, or MDF.

Raw panel edges can look unfinished and are prone to damage, moisture absorption, and wear. Edge banding provides a clean, professional look and enhances the strength and lifespan of the product. Whether in kitchens, office furniture, wardrobes, or retail displays, edge banding is a crucial finishing step in modern panel processing.

Key Functions of an Edgebander:

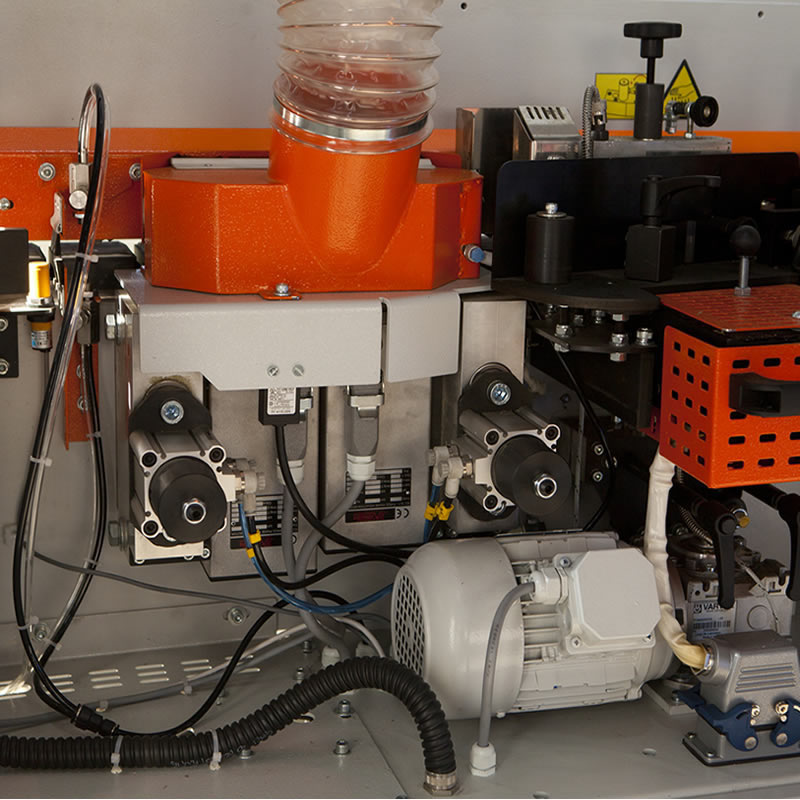

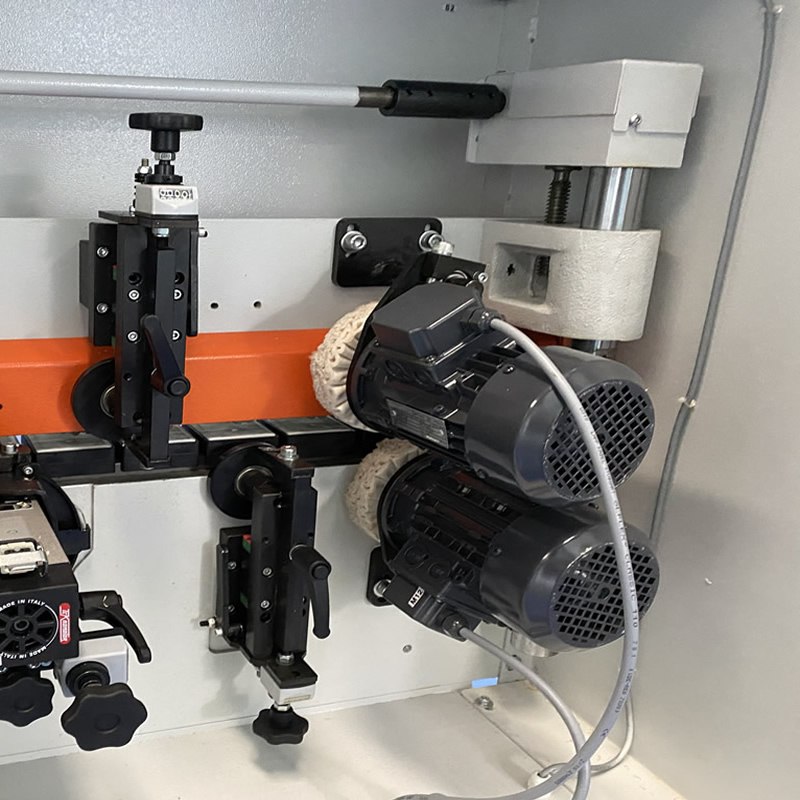

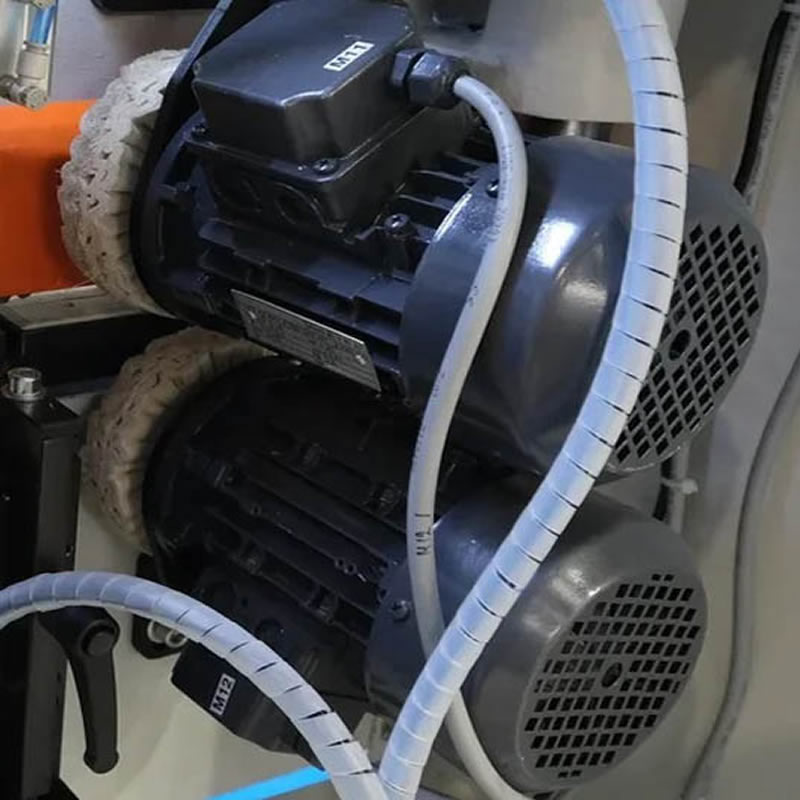

A modern edgebander performs multiple functions in a single, automated pass. These may include:

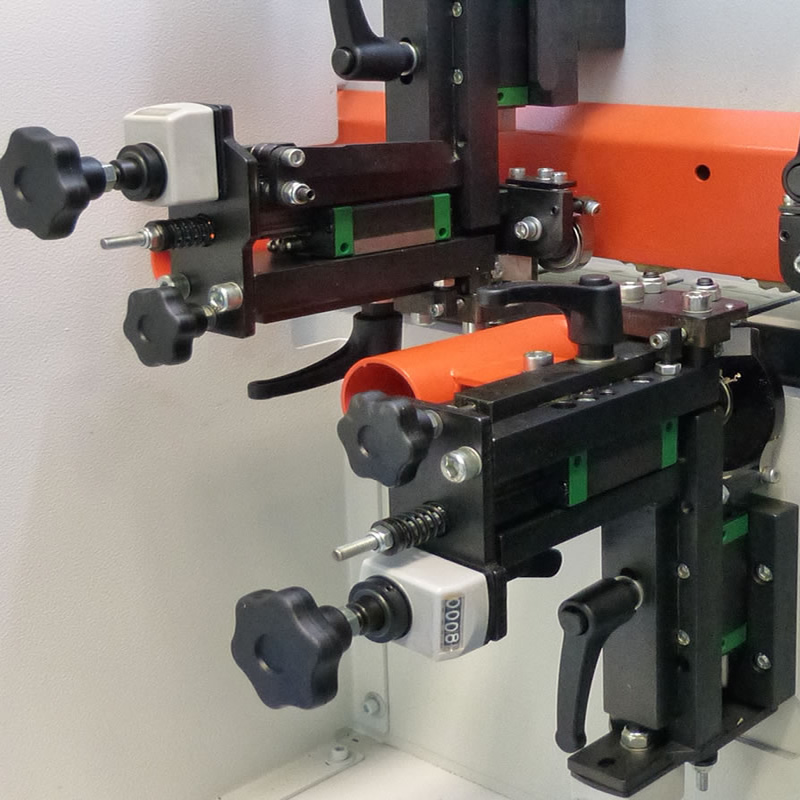

Pre-Milling – Smooths and prepares the edge of the panel for perfect glue bonding.

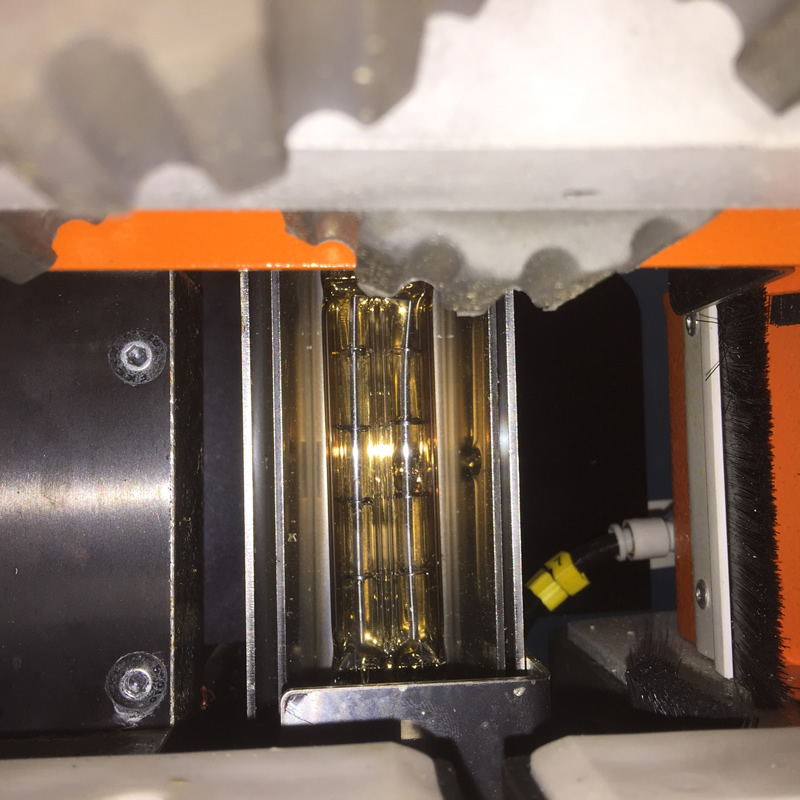

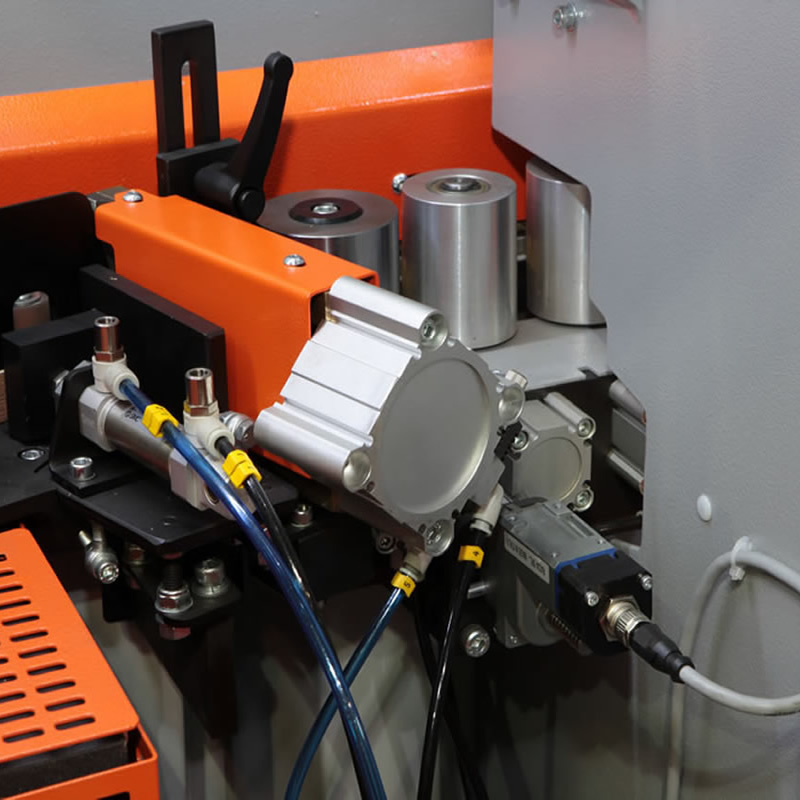

Glue Application – Applies glue (EVA or PUR) directly to the edge or the banding material.

Edge Banding Application – Feeds and presses the edge tape onto the board.

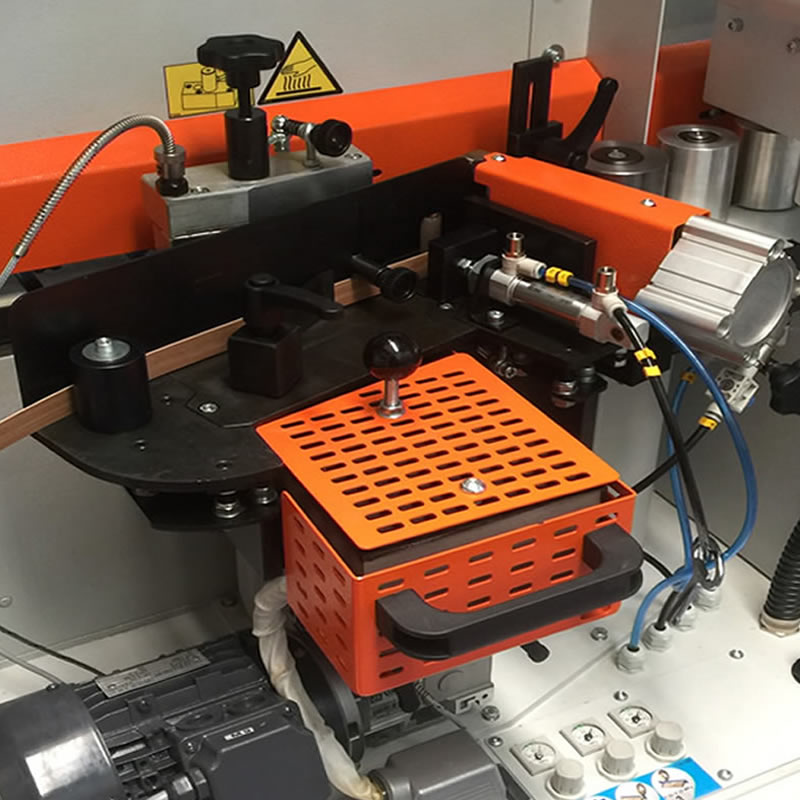

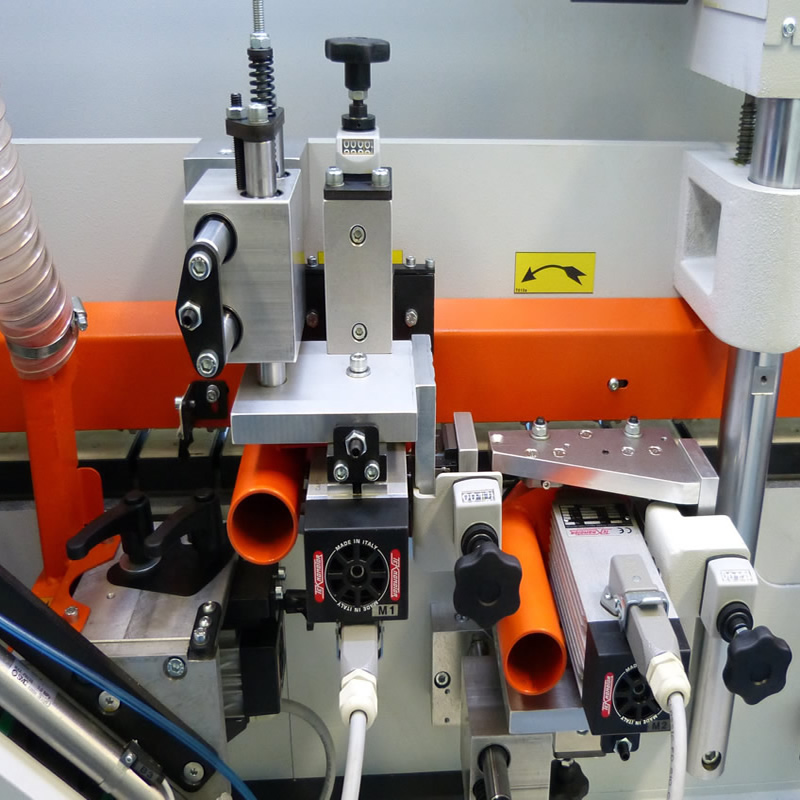

End Trimming – Cuts off excess edge tape at the front and rear of the panel.

Top and Bottom Trimming – Trims overhanging tape for a flush finish.

Corner Rounding (on advanced models) – Automatically rounds panel corners for a seamless look.

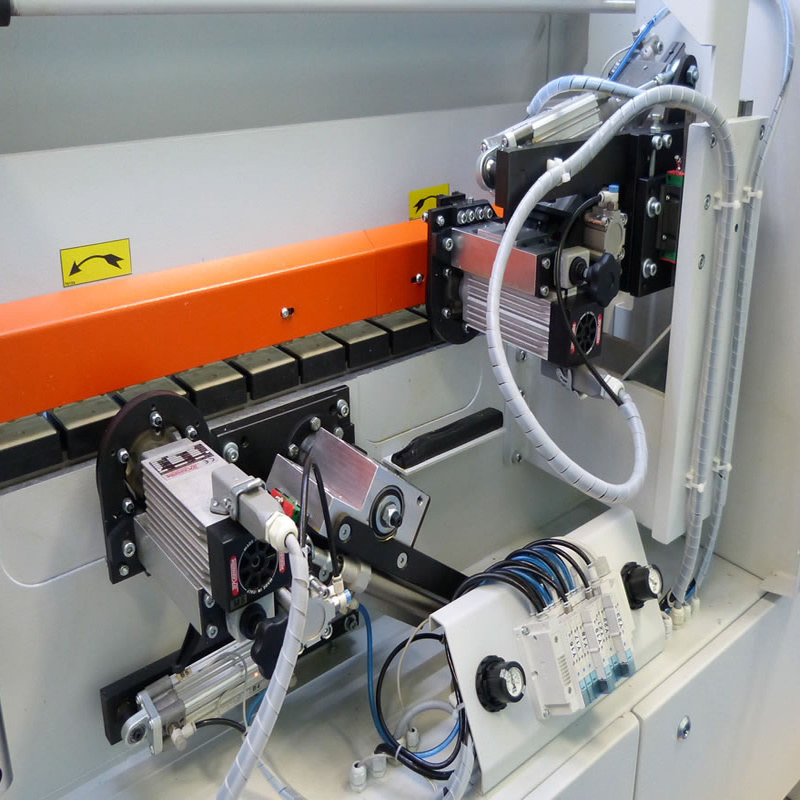

Scraping and Buffing – Cleans up and polishes the final edge for a premium finish.

Manual vs. Automatic Edgebanders

Manual Edgebanders: Suited for small workshops and occasional use. Require more operator input and are typically slower.

Semi-Automatic or Automatic Edgebanders: Ideal for high-volume production. Offer faster cycle times, consistent results, and reduced labour requirements.

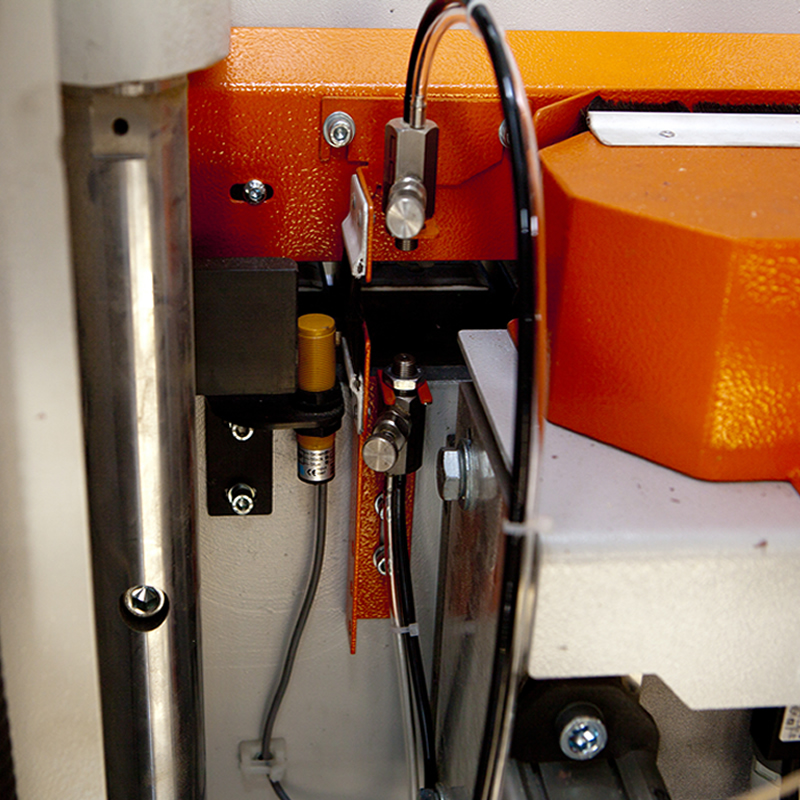

Advanced automatic machines may also include features like touchscreen controls, PLC systems, automatic glue pot cleaning, and servo-driven settings for efficiency and precision.

Looking to upgrade your edgebanding machine? Look no further than our selection of high-quality European Made edge bander machine for sale.

Our team also offers top-notch service to ensure your machines are running smoothly and efficiently.

Whether you're a professional woodworker or a hobbyist, we have the perfect edge bander to meet your needs.

If you're using an older model edgebander and encounter an error message, check the Unitronic controller for specific error codes.

Contact us today to learn more about our inventory and services.

Check our video - How to clean up glue pot on NikMann edgebanders!