🛠️ Extra Tape on the Back of the Panel – Check Sensor B1

Issue:

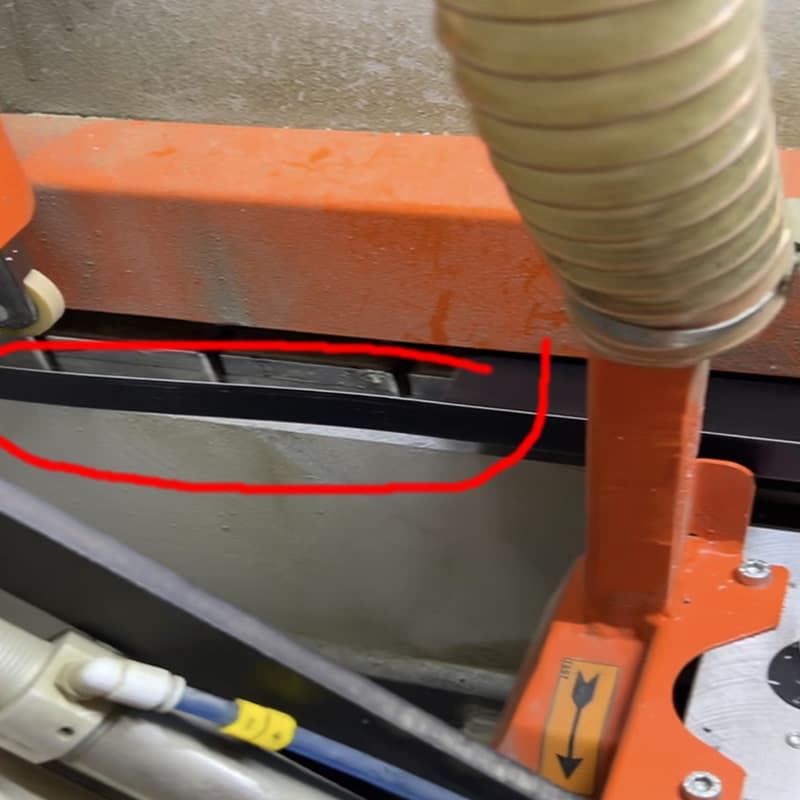

If your NikMann edgebander is leaving extra tape on the back of the panel, it is likely caused by a malfunction or misalignment of Sensor B1.

🔍 What is Sensor B1?

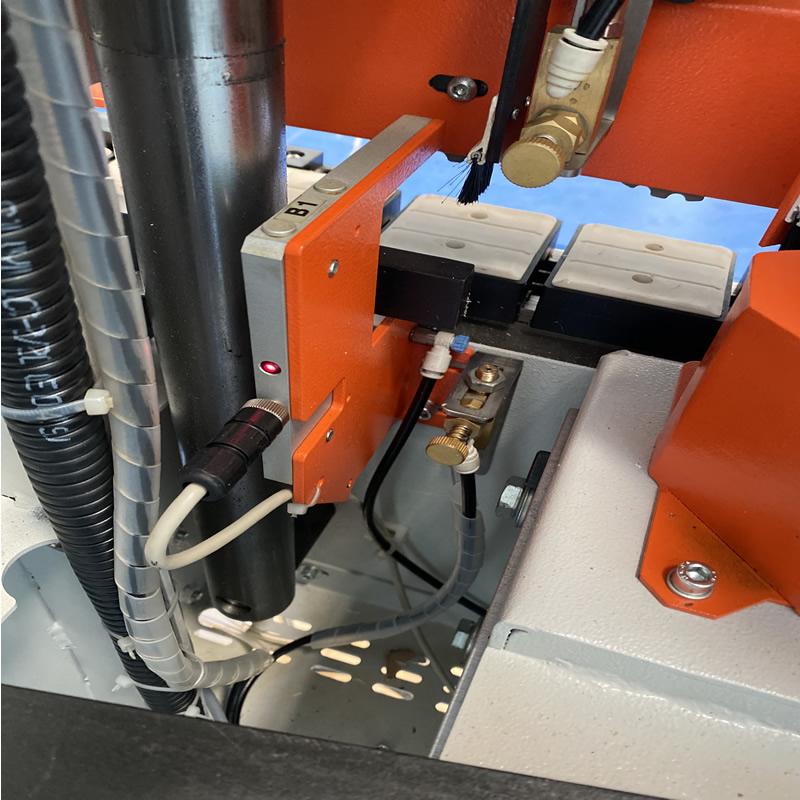

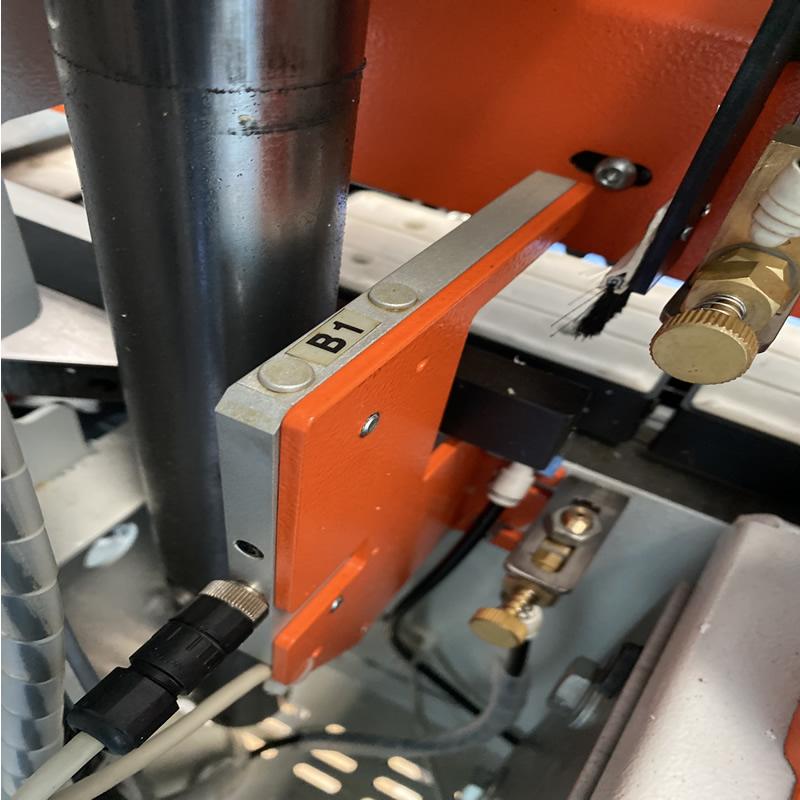

Sensor B1 is a laser sensor located on the right-hand side of the machine, next to the feed fence. It plays a critical role in the sequence timing of the edgebanding process by detecting panel position as it enters the machine.

⚠️ Why This Causes Extra Tape:

NikMann edgebanders use an integrated PLC with an HMI panel to control the workflow. If Sensor B1 fails or is obstructed:

The machine may not detect the end of the panel accurately

This causes the trimming or cutting units to delay, leaving excess tape on the trailing edge of the panel

✅ How to Fix It:

Visually Inspect Sensor B1

Ensure the lens is clean—wipe it with a dry cloth if dusty or dirty.

Check for any physical damage or wiring issues.

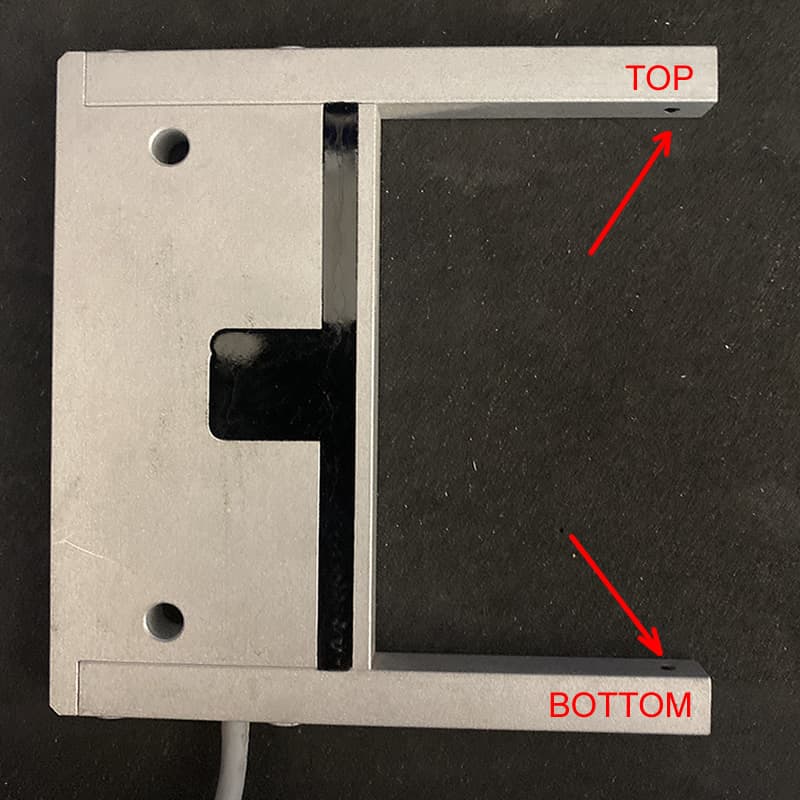

Verify Sensor Alignment

Sensor should be properly aligned with the feed path and unobstructed.

-

Check Sensor Status in HMI Panel

Go to diagnostics or sensor input status to verify if Sensor B1 is registering panel detection.

Reset and Test

Restart the machine and run a test panel to confirm the issue is resolved.

For more information, please call: 1300 436 792

WOODWORKING MACHINERY SERVICE

From emergency repairs to scheduled maintenance, sourcing spare parts or specifying a new woodworking machine - call 1300-436-792 for our expert advice and support.