Breakdowns, scheduled maintenance, on‑site support, spare parts and technical troubleshooting

At Forza Machinery, we specialise in professional edgebander repair and service in Melbourne. With over 25 years of experience supplying and maintaining woodworking machinery, our team provides fast, reliable, and cost-effective solutions for workshops of all sizes. From breakdown repairs to preventative maintenance, we ensure your edgebander stays in peak condition, minimising downtime and maximising productivity.

Why Choose Forza Machinery for Edgebander Service?

When your edgebander stops performing optimally, even small issues can disrupt your workshop. Forza Machinery provides expert repair services with a focus on efficiency, precision, and long-lasting results.

Our Melbourne-based services include:

On-site troubleshooting and repairs

Full inspection and maintenance of all edgebander units

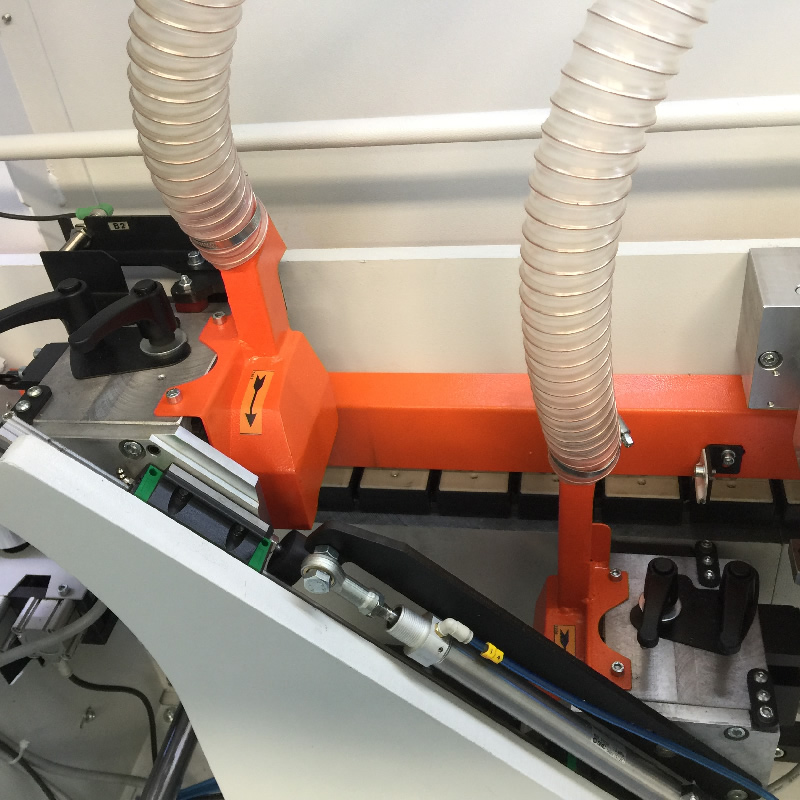

Glue pot cleaning and PUR adhesive system servicing

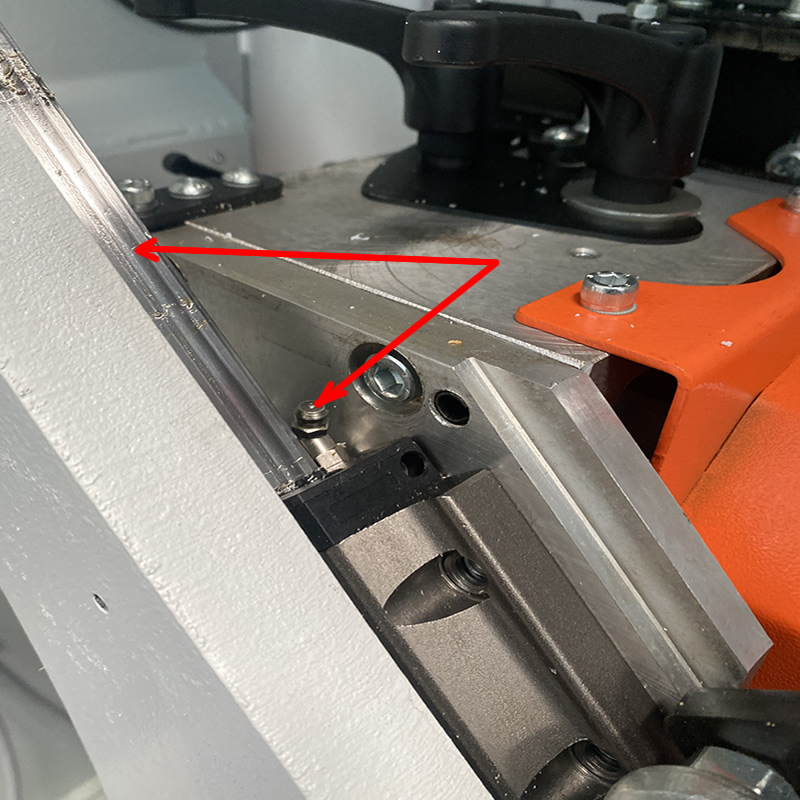

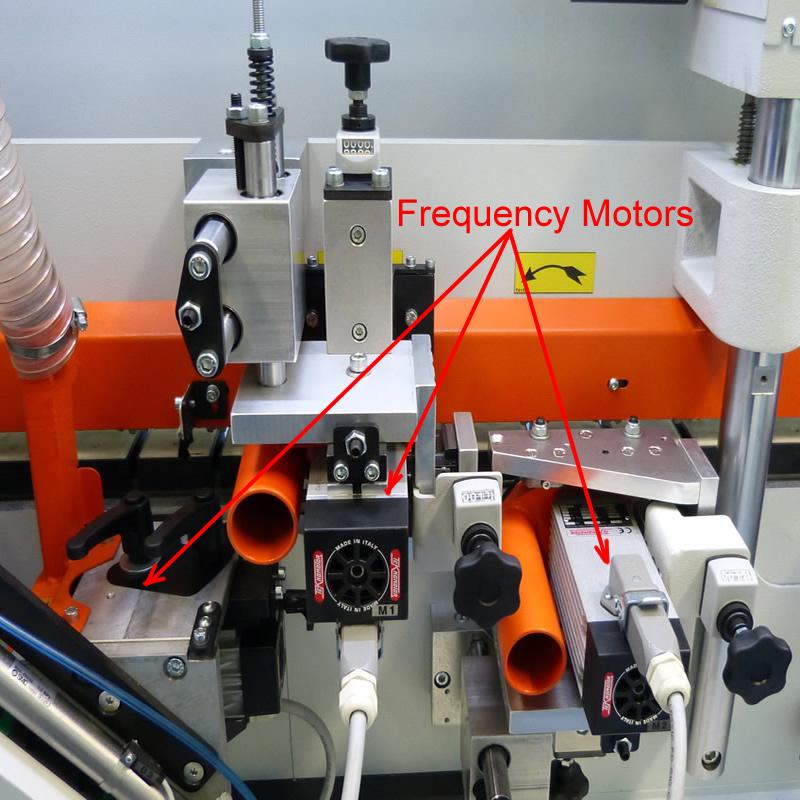

Trimming, end saw, and corner rounder adjustment

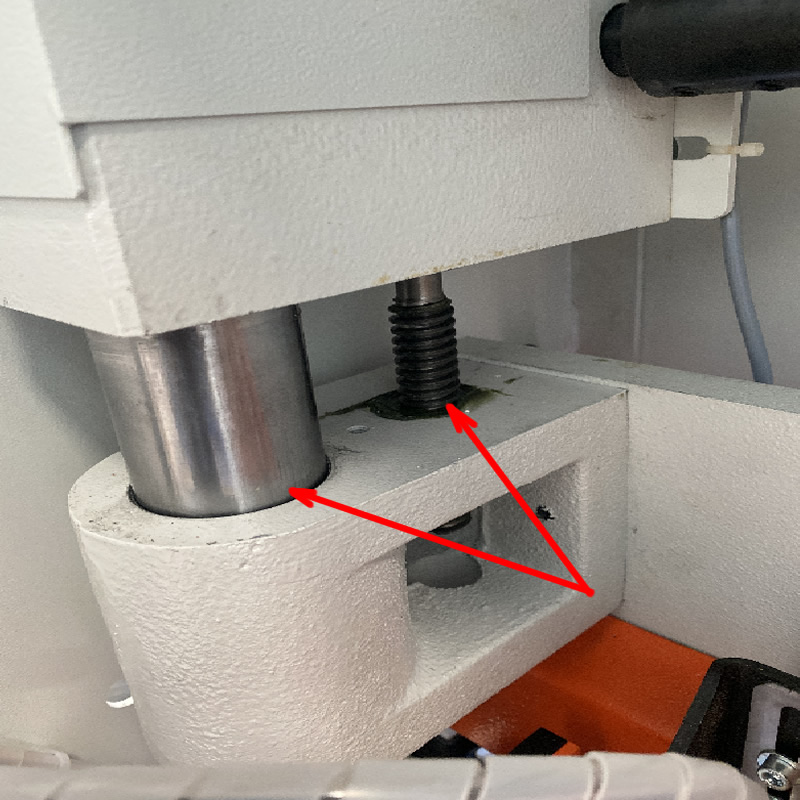

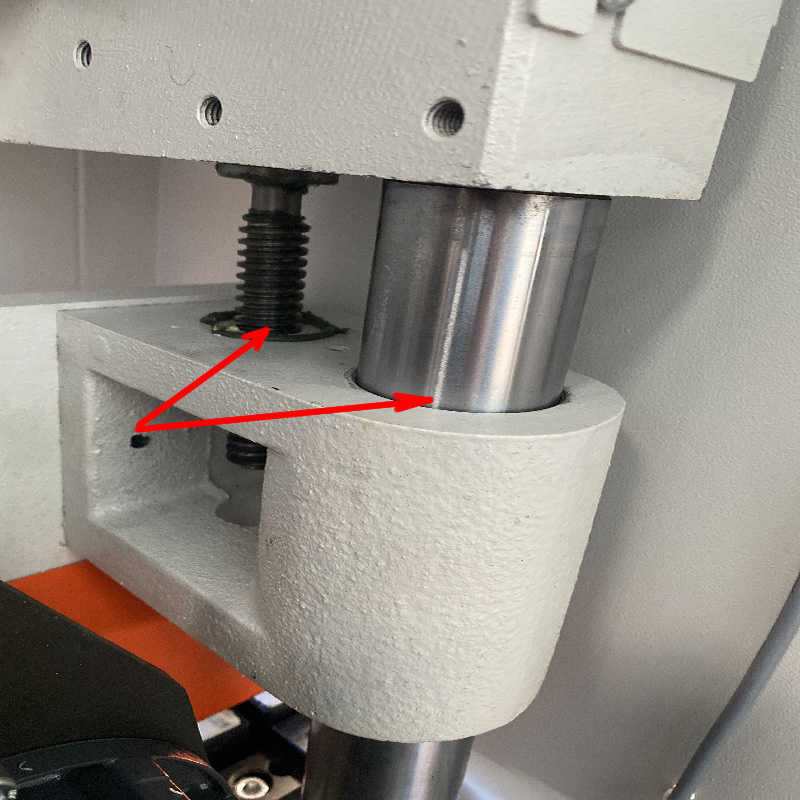

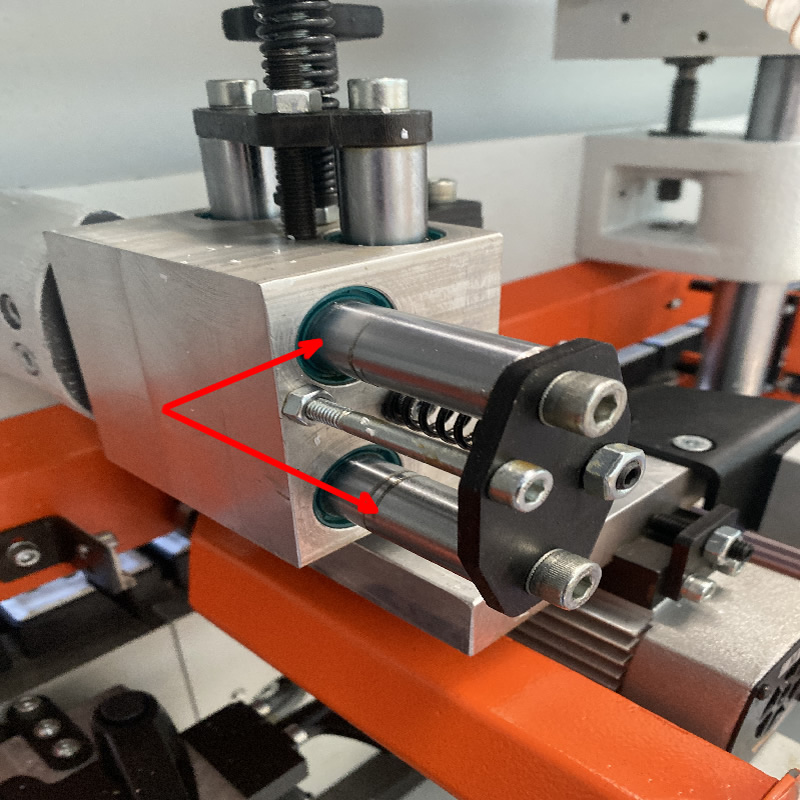

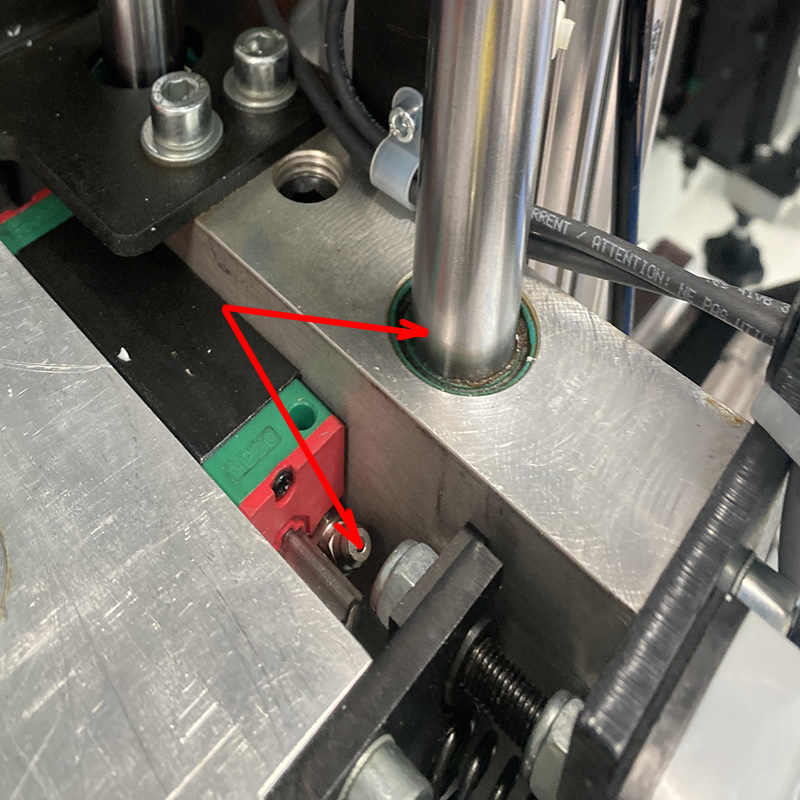

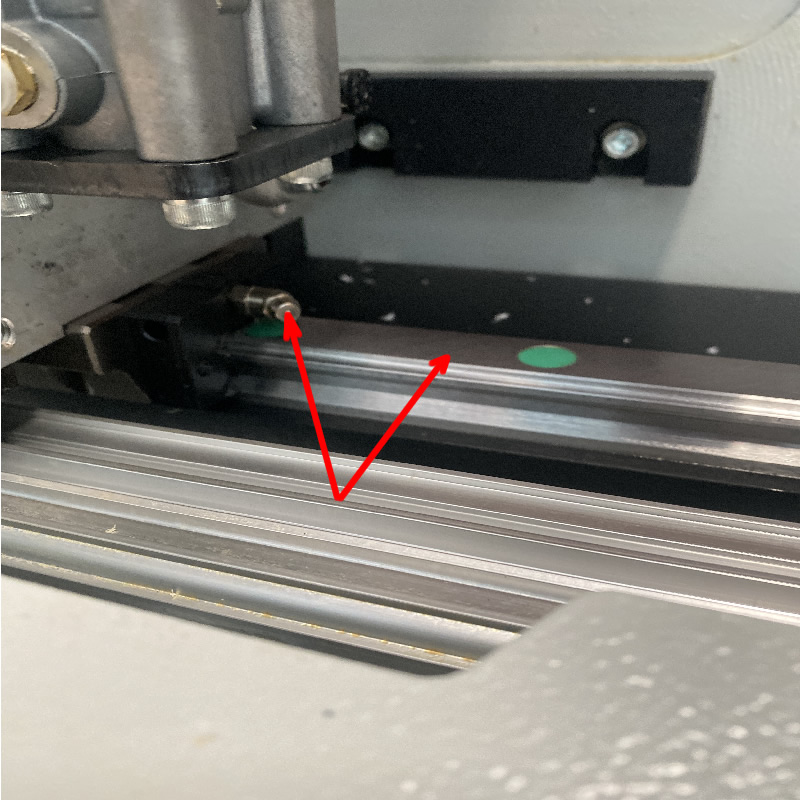

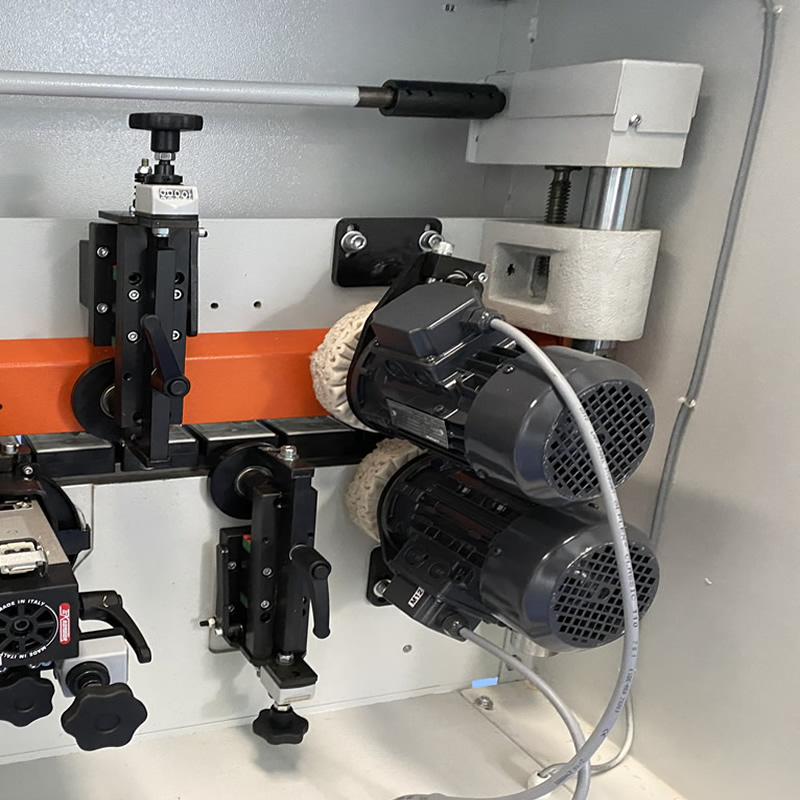

Roller alignment and calibration

Replacement of worn parts (cutters, bearings, belts, motors)

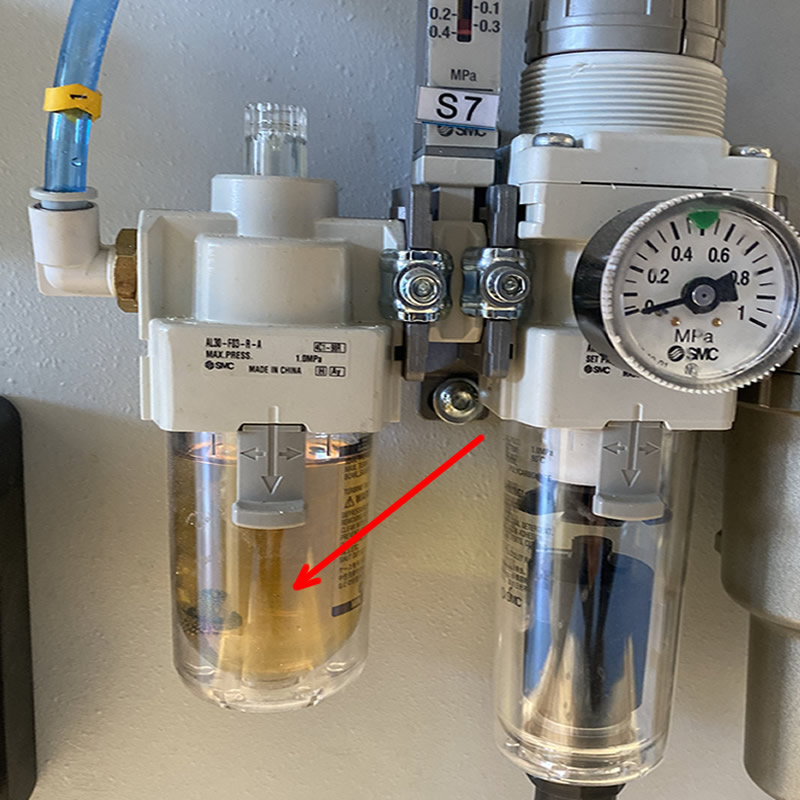

Electrical and pneumatic system checks

If you’re dealing with an edgebander that's in need of repair, here are some steps you might consider:

1. IDENTIFY THE PROBLEM: Try to diagnose the issue as accurately as possible. Common problems include uneven application of adhesive, malfunctioning rollers, or alignment issues.

2. CONSULT THE MANUAL: Your edgebander’s manual should have troubleshooting sections that can help you identify and fix common problems.

3. CHECK FOR OBVIOUS ISSUES: Look for any visible damage or wear on components such as the feed rollers, glue pot, or trimming tools.

4. CLEAN THE MACHINE: Sometimes, simply cleaning the machine and removing any buildup can solve performance issues. A clean and organized workspace improves efficiency and reduces the risk of errors. Keep your edgebander and surrounding area free from debris, dust, and adhesive residue. Regularly clean the machine components, such as rollers, blades, and glue pots, to ensure optimal performance.

5. REPLACE WORN PARTS: If you’ve identified any worn or damaged parts, replacing them might solve the problem. Make sure to use parts that are compatible with your specific model.

6. SEEK PROFESSIONAL HELP: If you’re unable to fix the issue yourself, contacting a professional repair service might be necessary. Look for a technician who specializes in edgebanders and edge banding machines or woodworking machinery.

7. REGULAR MAINTENANCE: To prevent future issues, make sure to perform regular maintenance on your edgebander, including cleaning and checking for worn parts.

If your edgebander is one of the older models and displays an error message, check the Unitronic controller for error codes.

If you need a specific repair service, please call: 1300 4 FORZA !