Versatile edgebander with lightning-fast setups, compact design, and a VERY AFFORDABLE price.

For professional woodworking shops and furniture manufacturers seeking a reliable, high-performance solution for edge banding, the NikMann-RTF Edgebander is an outstanding choice.

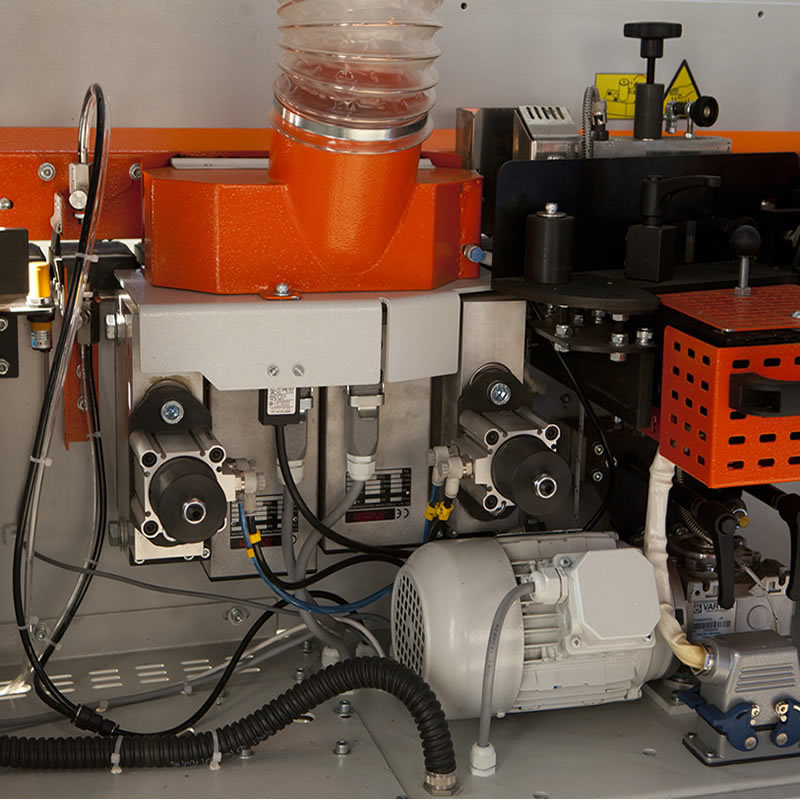

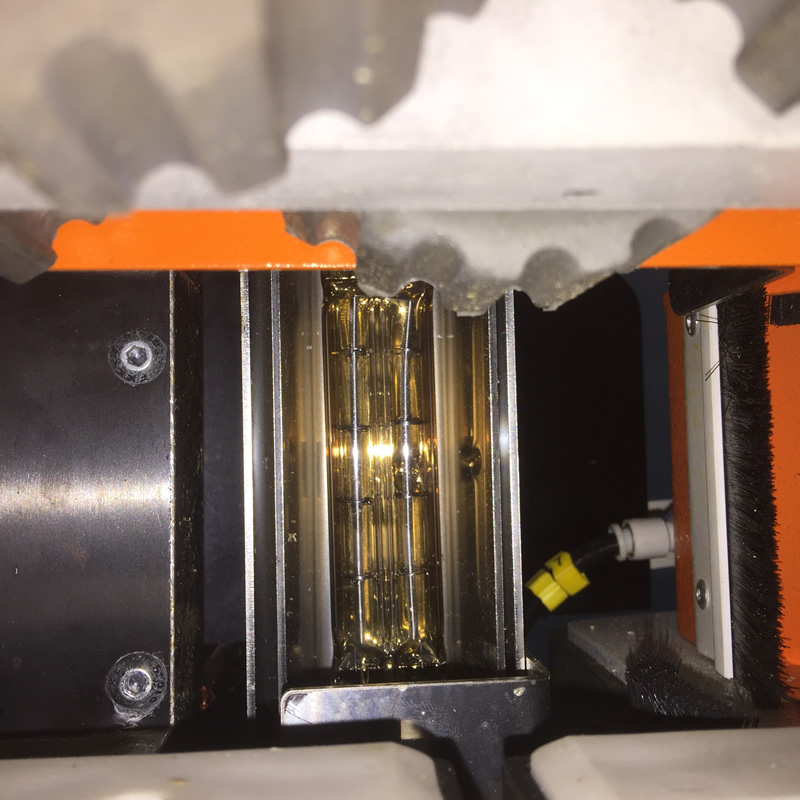

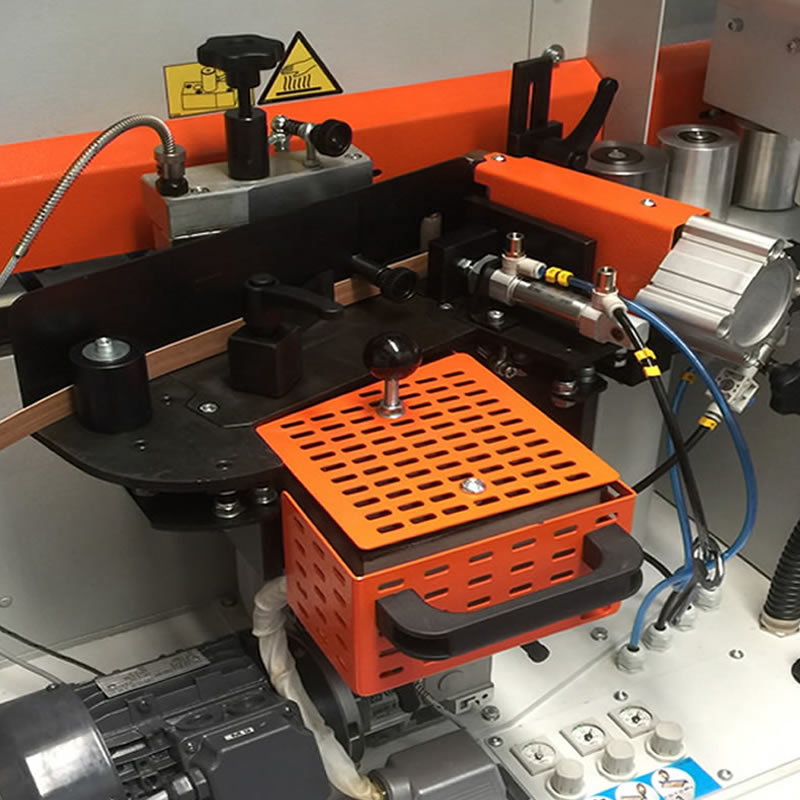

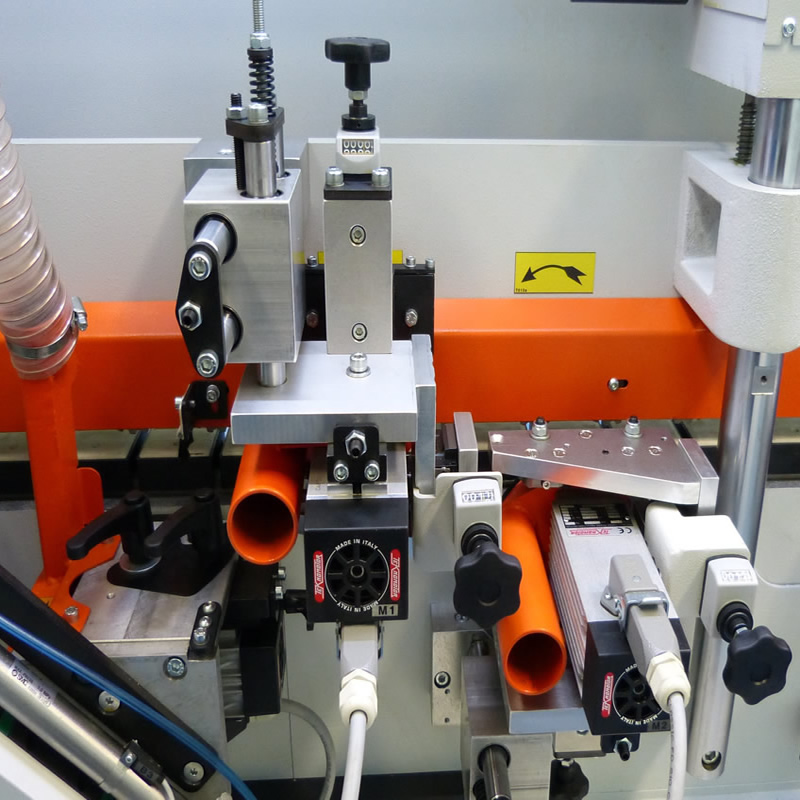

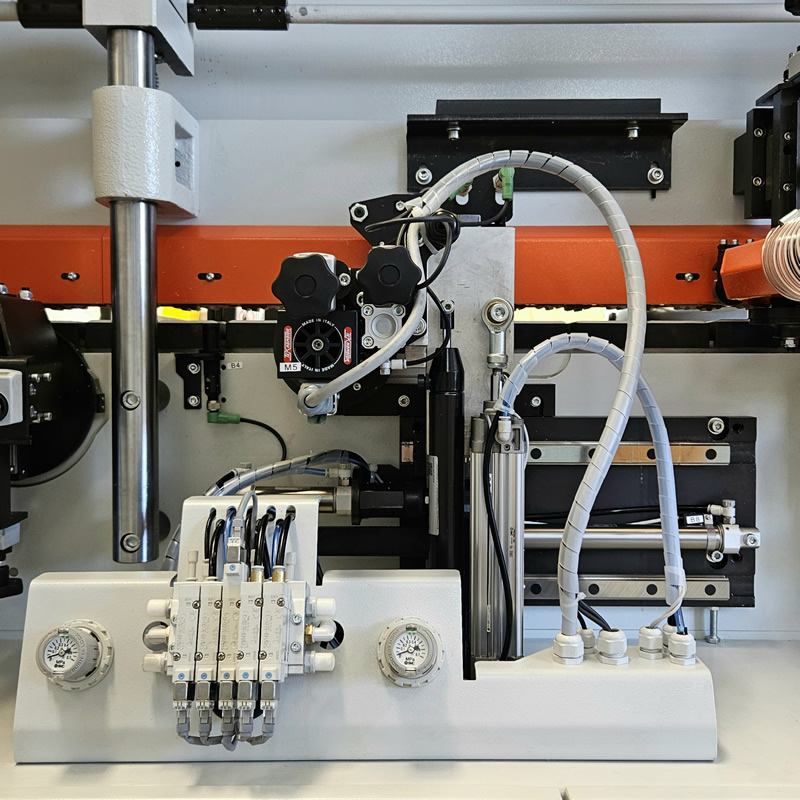

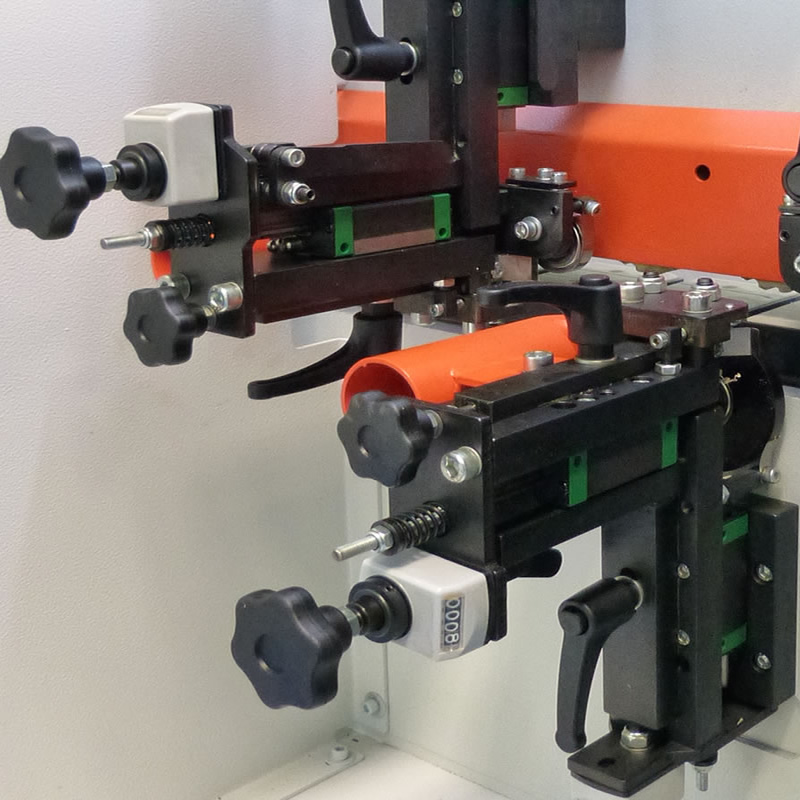

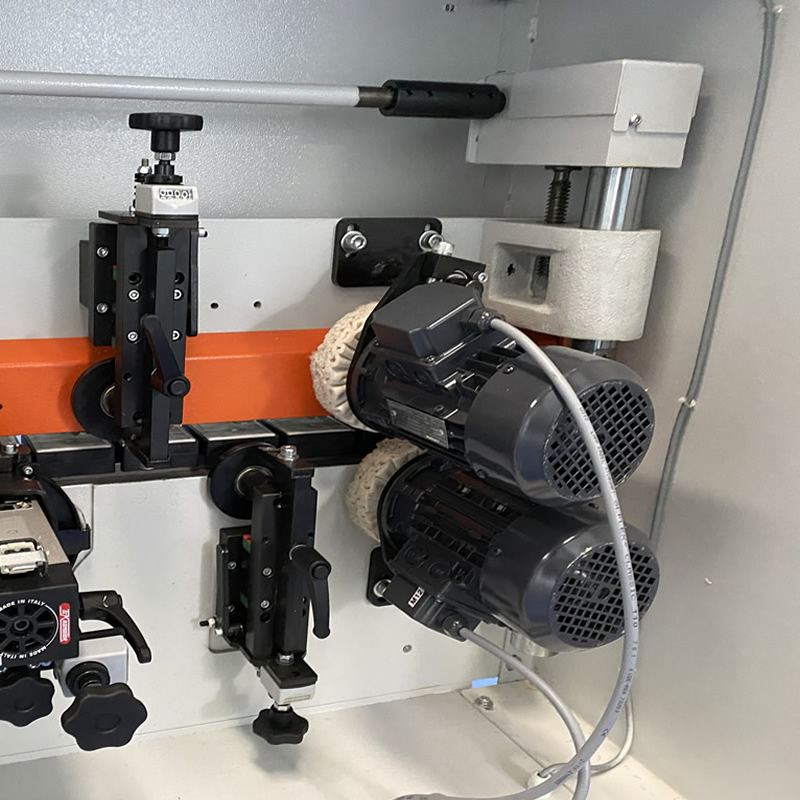

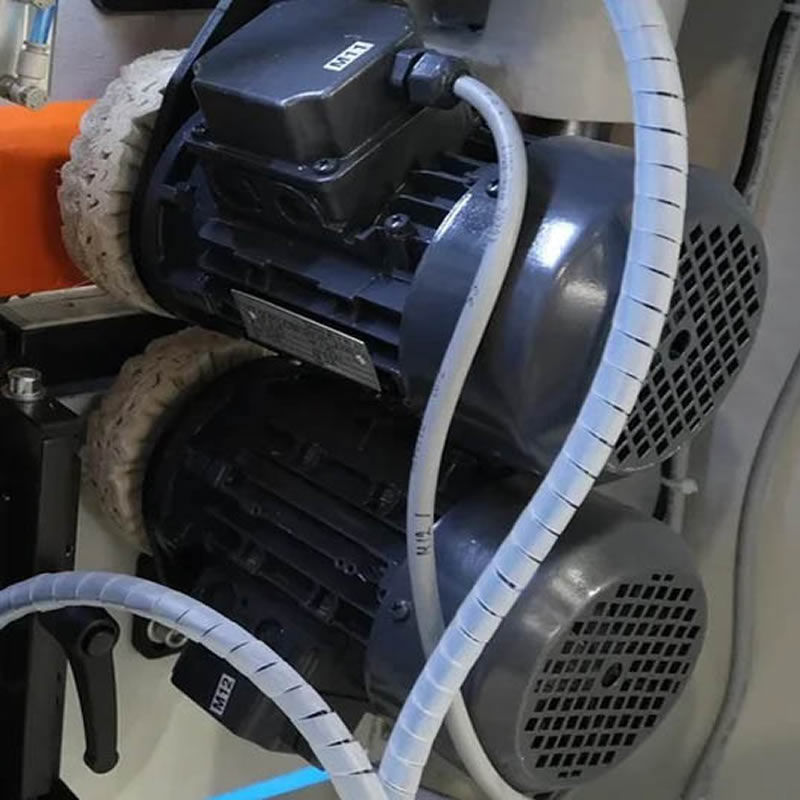

Manufactured in Europe and built to exacting standards, this industrial-grade machine is designed for continuous, high-precision edge banding operations. With advanced features such as pre-milling, EVA glue application, trimming, scraping, and buffing, the NikMann-RTF ensures a seamless and durable edge finish on a variety of materials.

For more information on edgebanders and edge banding machines, read our comprehensive guide: The Ultimate Guide to Choosing Edgebanders for Australian Cabinet Makers.