Types of Industrial Woodworking Machines

Industrial woodworking machines are essential tools used in large-scale and professional woodworking operations.

These machines are designed to handle high volumes, precision, and durability, making them suitable for producing furniture, cabinetry, flooring, and other wood products.

Below is an overview of common types of industrial woodworking machines and their functions:

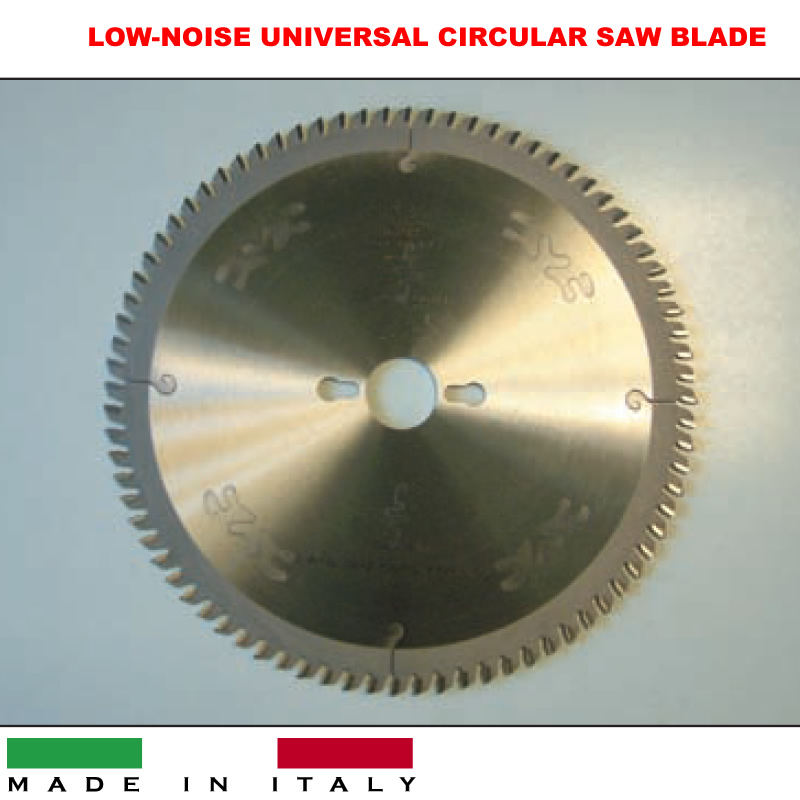

1. Cutting Machines

-

Table Saws: Used for precise straight cuts. Often equipped with sliding tables for large panels.

-

CNC Routers: Automated machines for cutting, carving, and engraving complex shapes and patterns.

-

Panel Saws:Specifically designed for cutting large sheets of plywood or MDF.

-

Band Saws: Ideal for cutting curves and intricate shapes in wood.

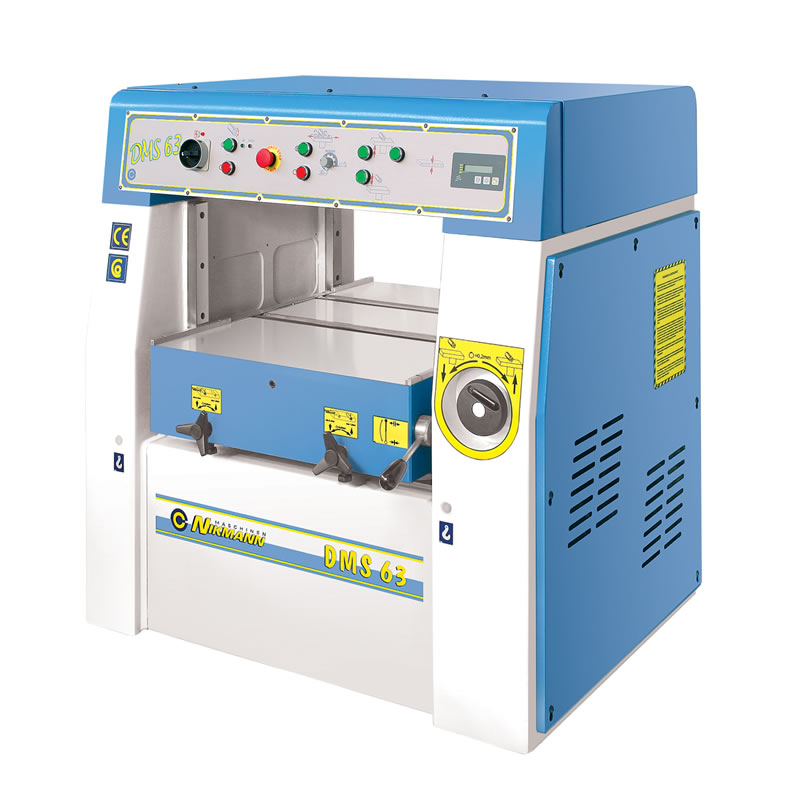

2. Planing and Surfacing Machines

-

Planers: Smooth and reduce wood thickness uniformly.

-

Jointers: Flatten and square wood edges, preparing them for joining.

-

Wide Belt Sanders: Sand large surfaces for a smooth finish.

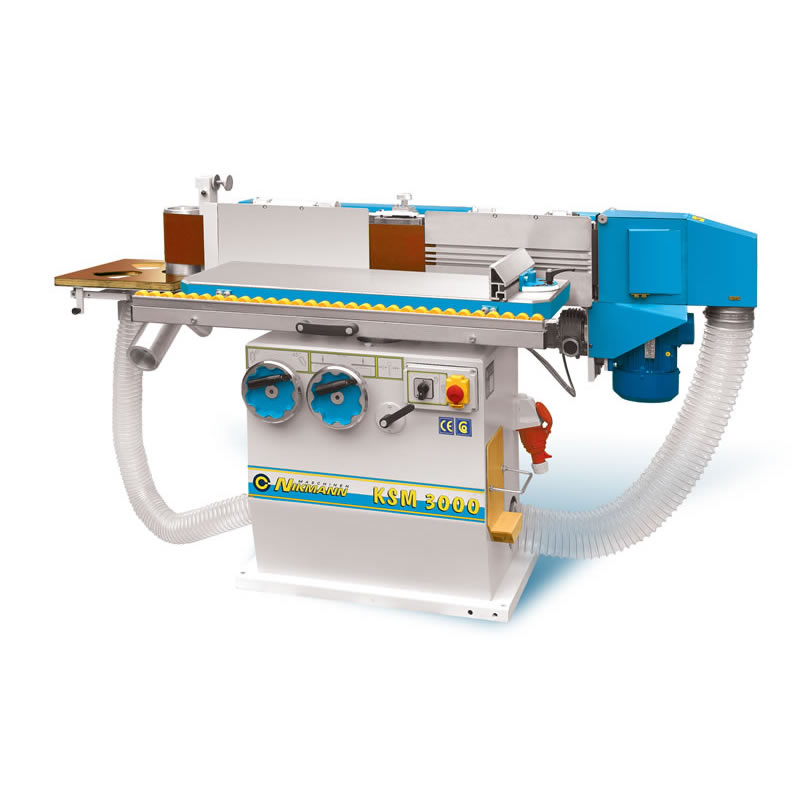

3. Shaping and Profiling Machines

-

Moulders: Create detailed profiles on wood, such as crown molding or baseboards.

-

Shapers: Similar to routers but more robust, used for creating edges and profiles.

-

Edge Banders: Apply thin strips of material (banding) to the edges of panels.

4. Assembly and Finishing Machines

-

Clamping Systems: Ensure precision during assembly by holding parts in place.

-

Spray Booths: For applying finishes like paint or varnish.

-

Laminating Machines: Bond layers of wood or apply veneers.

5. Drilling and Boring Machines

-

Multi-Spindle Drills: Drill multiple holes simultaneously, often used in cabinetry.

-

Horizontal Boring Machines: For precision hole alignment in furniture making.

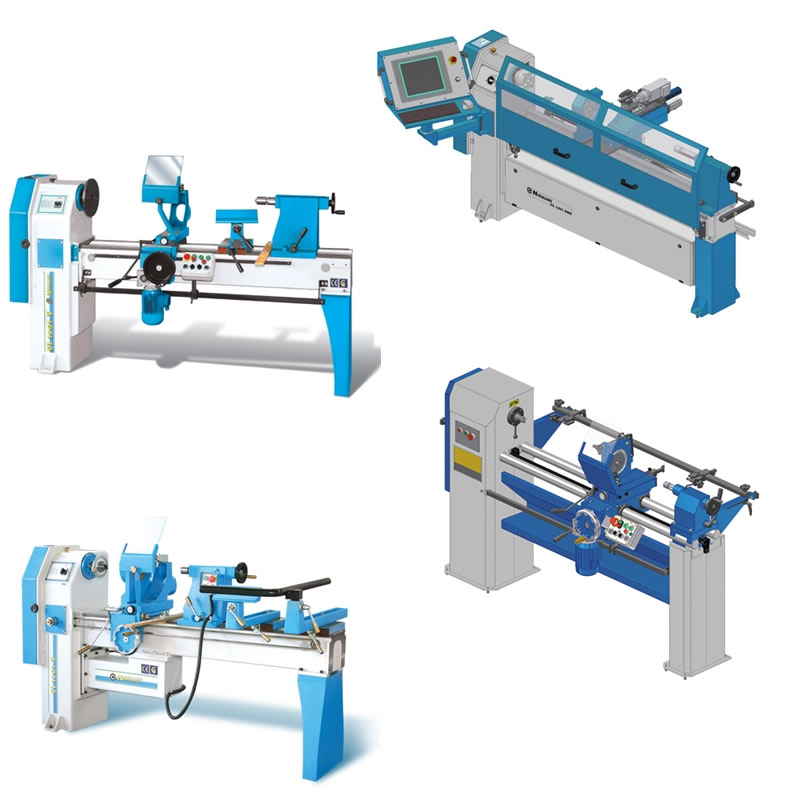

6. Specialized Machines

-

Wood Lathes: Turn wood into cylindrical shapes (e.g., table legs).

-

Finger Joint Machines: Create strong joints for wooden boards.

-

Tenoning and Mortising Machines: Precision cutting for joints.

Explore Forza Machinery’s reliable, European-made wood working machines today!

For more information, please call: 1300 436 792

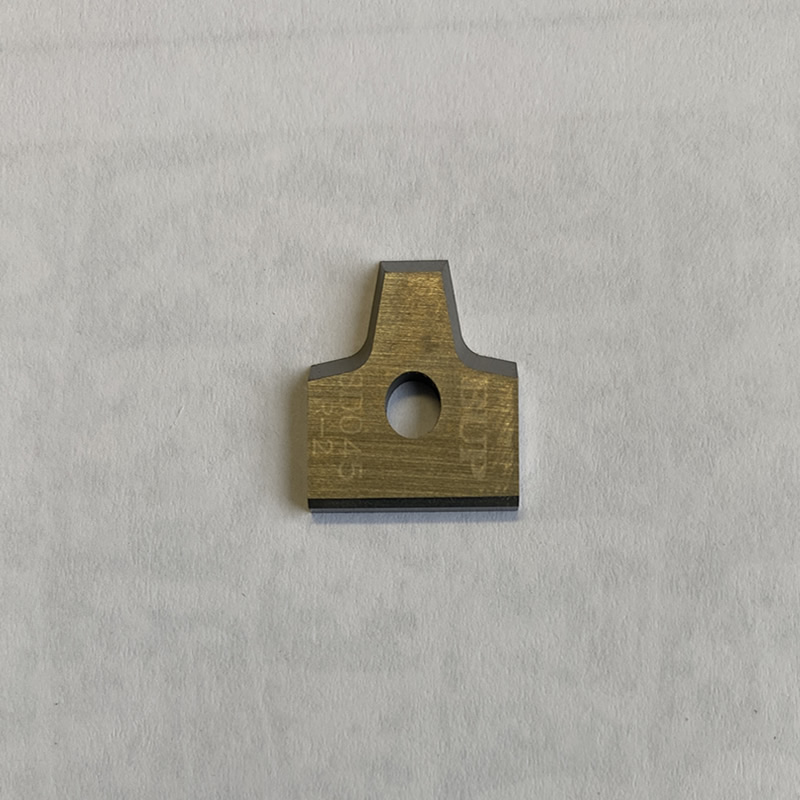

SPARE PARTS and TOOLS

Key Features of Industrial Woodworking Machines

-

Automation: Many machines are CNC-controlled, allowing for repeatability and precision.

-

Durability: Built with heavy-duty materials to withstand long hours of operation.

-

Versatility: Adaptable for various materials and project scales.

-

Safety Features: Integrated safety mechanisms like emergency stops, guards, and dust collection systems.