Edgebanders SERVICE and MAINTENANCE

Forza Machinery REPAIR and SERVICE most type and models of edgebanders and edge banding machines in a metro Melbourne, country Victoria and interstate.

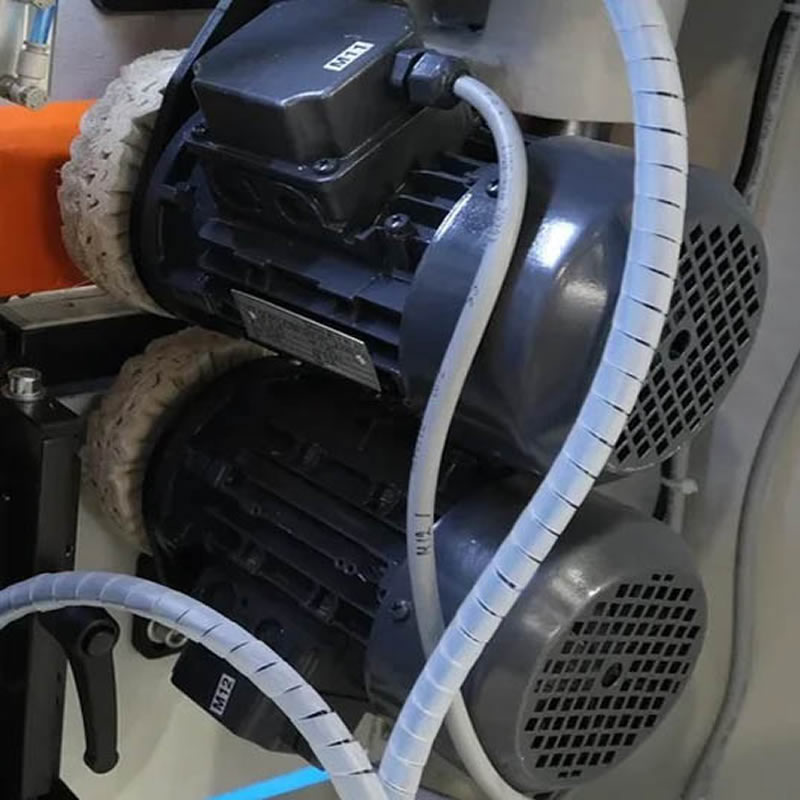

Start by performing regular cleaning, maintenance and lubrication on the units of your edgebander. Correct glue setup, clean units and sharp tooling are the key for reliability and finish quality of any edgebander. After you have reviewed your machine's manual, you will typically see that the following steps should be followed in properly maintaining your machine.

Here are some key features for General Service and Maintenance for edgebanders:

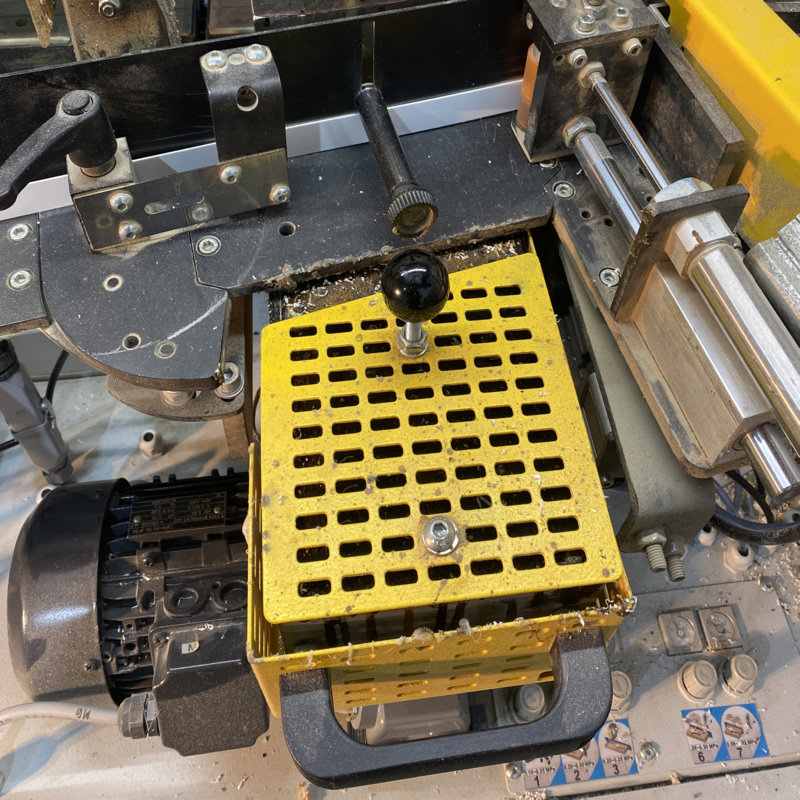

- Cleaning: Clean the edgebander at least once a day to prevent jams and keep it running well. You can use only a vacuum cleaner for electrical cabinets;

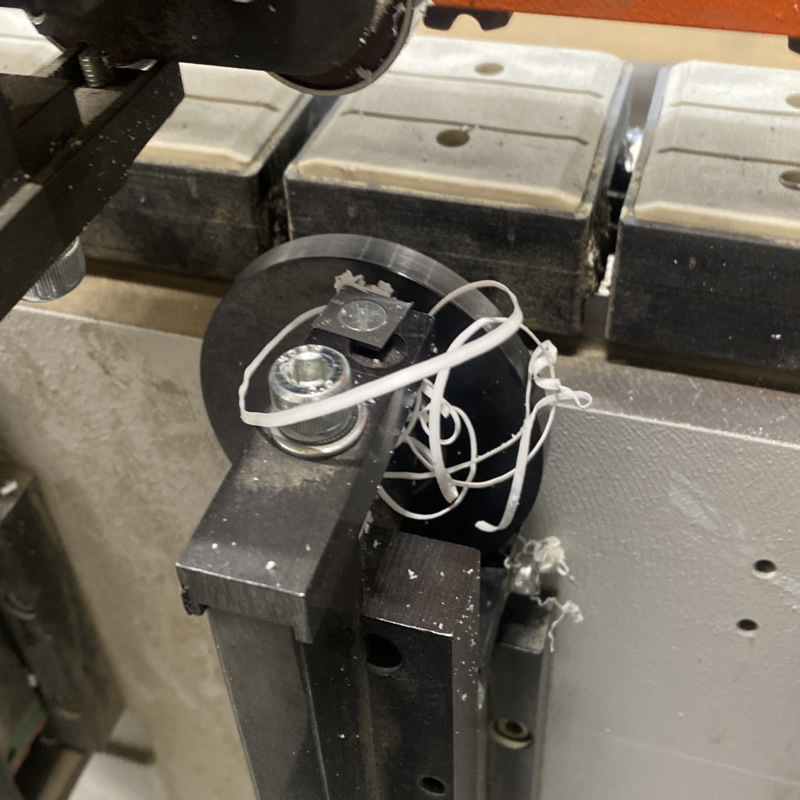

- Lubrication: Lubricate the feed track chain, glue pot and linear bearings regularly. You can use High Temperature grease for the glue pot;

- Compressed air: Check the air regulator to ensure there is oil in the reservoir;

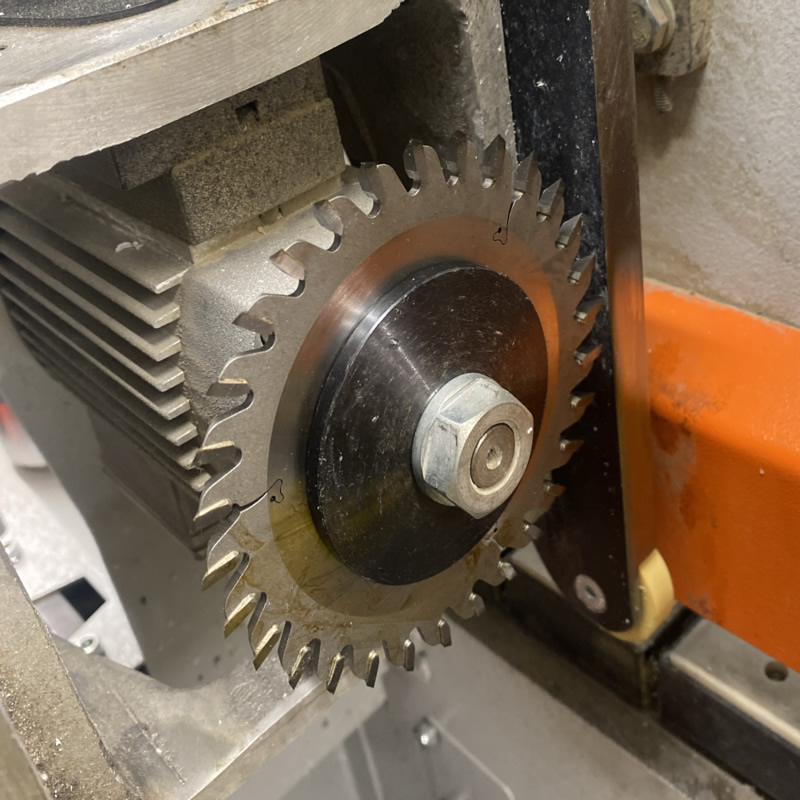

- End saw blades: Before installing new blades, clean the area where the blades are mounted;

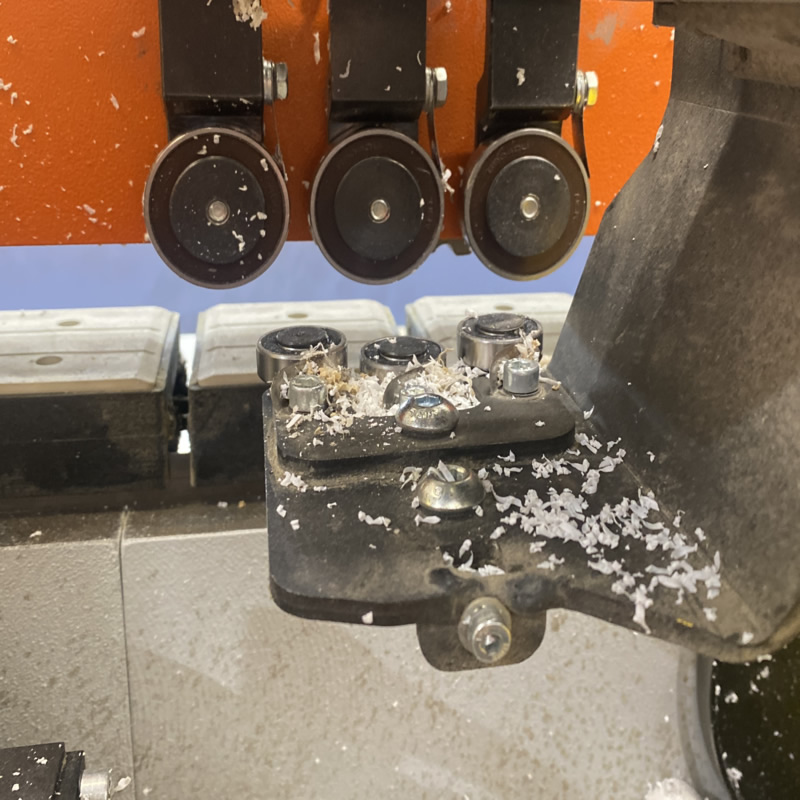

- Fine trimmers: Replace the blades on fine trimmers to ensure quality and precision;

- Universal joint: Clean and lubricate the universal joints to maintain smooth operation;

- Tracing shoes: Check the tracing shoes for wear and replace them if needed;

- Flat scraping unit: Ensure the flat scraping unit is adjusted correctly to remove residual glue.

We can help you avoid service calls through the Forza Machinery Maintenance Program, an investment that can minimize repair costs and keep your production running smoothly. Forza Machinery technicians can troubleshoot and solve potential problems before they happen.We will inspect your edgebanding machines and perform regular maintenance regardless of the manufacturer.

Preventive Maintenance Inspection

Edgebanders require regular Service and Maintenance to ensure they continue to function properly and to prolong their life:

Check Out Our Selection of European Made NikMann edgebanders!