🔴 ALARM-02 on NikMann edgebanders

Any of the asynchronous motrs is overheated!

🔍 What Does ALARM-02 Mean?

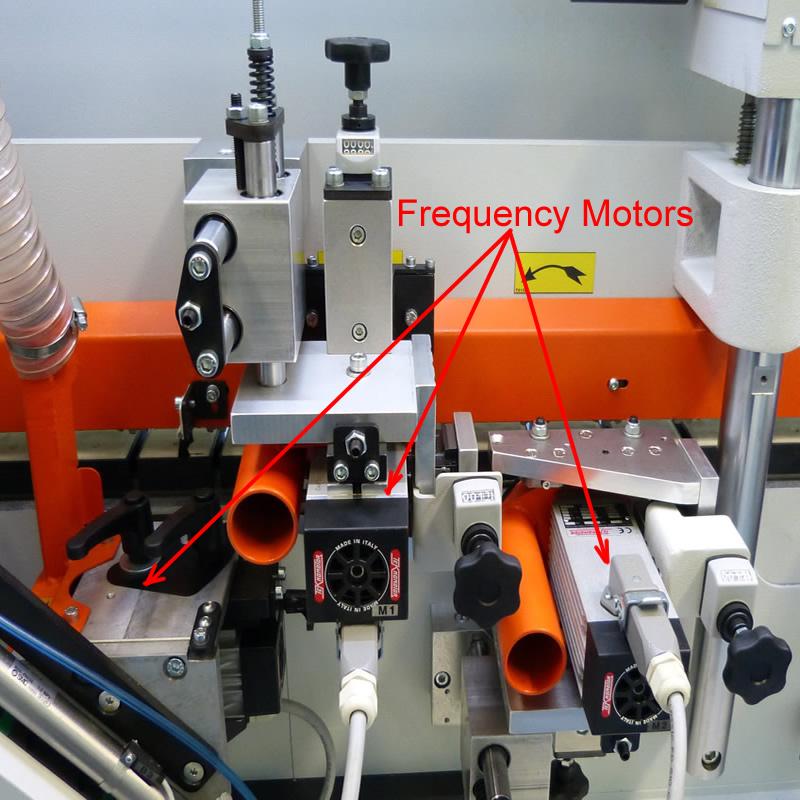

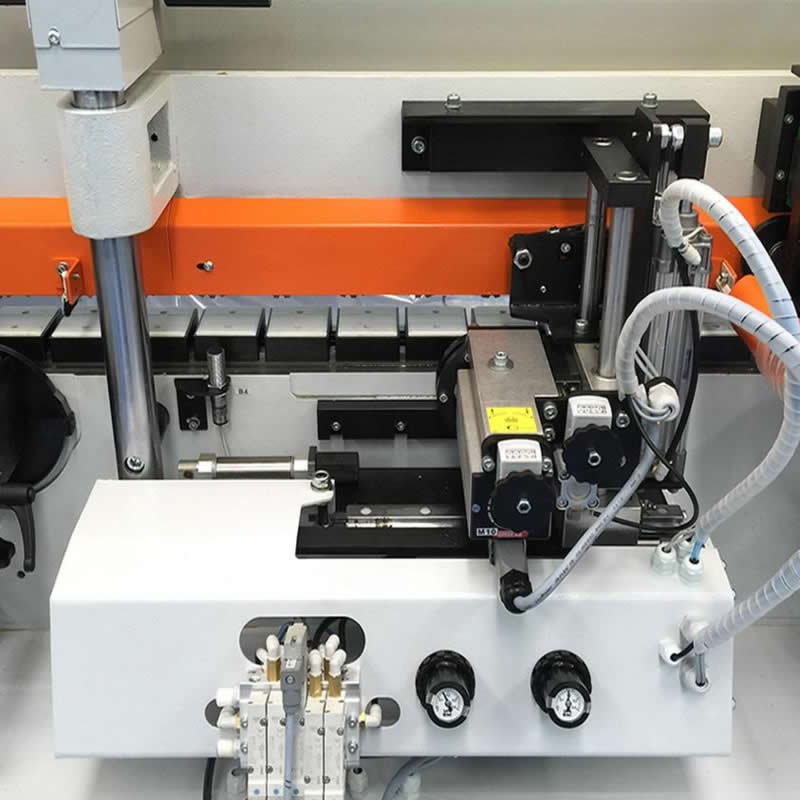

When ALARM-02 is triggered on NikMann edgebanders, it means that a motor used in one of the processing units—such as the pre-milling, glue spreading, end trimming, corner rounding, or buffing units has reached a temperature above the safe operating threshold. This is usually caused by overload, insufficient cooling, poor ventilation, or mechanical resistance within the motor.

Asynchronous motors are widely used in NikMann machines due to their reliability and efficiency. However, if these motors operate under stress or for prolonged periods without rest, they can overheat. To prevent permanent damage, the system uses thermal sensors (often PTC thermistors) to monitor motor temperature in real time.

For more information, please call: 1300 436 792

🖥 What Happens on the HMI?

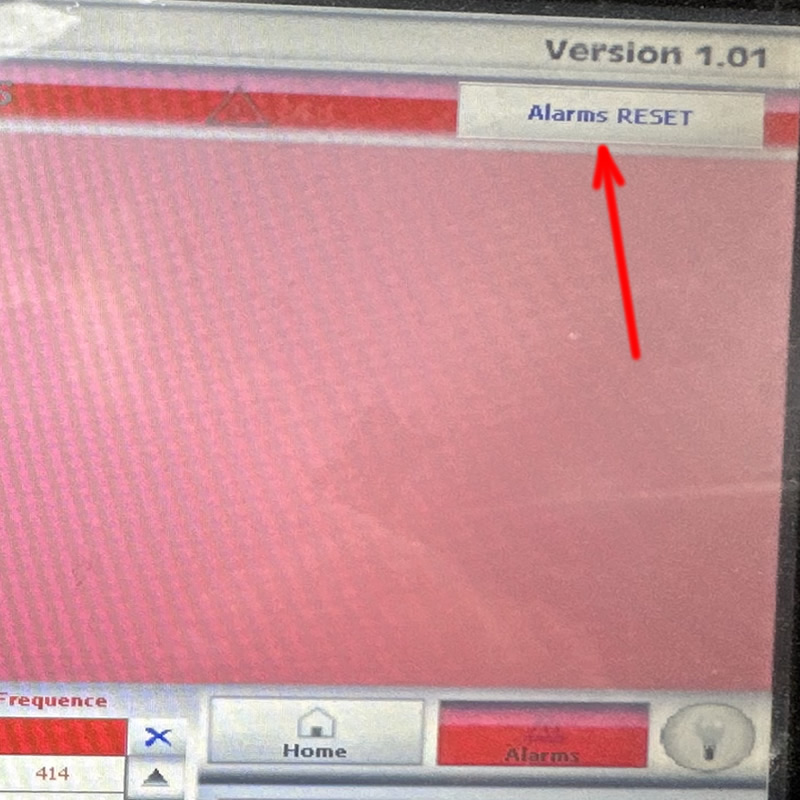

If you are on the HOME SCREEN when ALARM-02 is triggered, the HMI (Human-Machine Interface) will automatically switch to the ALARMS SCREEN. This screen provides:

The alarm number (ALARM-02)

A clear explanation: “Any of the asynchronous motors is overheated!”

A troubleshooting section for resolving the issue

If you are not on the HOME screen, you can manually access the alarm status by navigating to the “ALARMS” screen from the main menu.

This screen also shows:

Activation time;

Alarm type;

Reset time (once resolved)

Number of times each alarm type has occurred (useful for tracking recurring issues)

⚠️ Causes of Overheating

Common reasons for asynchronous motor overheating include:

Blocked or dirty cooling fans

Excessive load or mechanical resistance;

Extended continuous operation without rest;

Dust or glue buildup causing friction;

Electrical issues or poor ventilation inside the control cabinet.

✅ Troubleshooting ALARM-02

-

Shut Down the Machine Safely

Turn off the main power and wait for all moving parts to stop.

-

Let the Motor Cool

Wait 15–30 minutes to allow the affected motor to cool naturally.

Inspect Cooling Fans and Vents

Ensure air inlets and cooling fans are clean and functioning properly.

Check for Mechanical Resistance

Inspect moving components of the motor (e.g., belts, pulleys, cutter heads) for binding or debris.

-

Restart the Machine

Once everything is clean and the motor is cool, power on the machine.

-

Reset the Alarm

Go to the ALARMS screen and follow the instructions to reset ALARM-02.